What Moldmakers Should Know about Cylindrical Grinding

Reducing costs, producing superior surface finishes and providing high flexibility are just a few of the advantages achieved with cylindrical grinding in mold manufacturing.

When we talk about the moldmaking industry, we’re addressing a very large spectrum of applications. The high-volume automotive market aside, we can examine the lower-volume, highly precise molds for medical components, molds for the food and beverage industry, cosmetics and more.

In the food and beverage industry it’s common for molds to have many radii, which necessitate blending and raises the issue of surface finish and polishing. One of the serious aspects moldmakers in this segment are concerned with is minimizing polishing. From the grinding standpoint, features must be ground to enhance surface finishes in an attempt to reduce the polishing burden—sometimes even eliminating it.

A typical method to do this is by using multiple steps. Using a roughing wheel and a finishing wheel, you rough out the part and then you finish it with a finishing wheel that has a finer grit, removes less stock, with the result of a better finish.

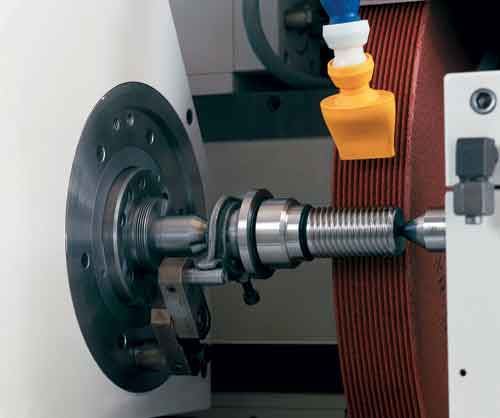

Another combination of steps is pre-hard turning followed by finish grinding. Here, some of the cavity material can be removed with the boring tool or a turning insert and then finished by finish grinding. So it’s entirely possible to have a variety of multi-step processes going on in a single fixturing, in a single cylindrical grinding machine.

Machine Considerations

Moldmakers need to consider all of the possible configurations of a potential cylindrical machine. How is the machine equipped? What type of wheel head configuration? Does it have multiple OD wheels, multiple stations, a swiveling turret wheelhead with direct drive? The same questions can be asked regarding internal grinding. Does the machine have multiple ID spindles, for example?

What about a C-axis? Grinding threads and forms requires a C-axis, plus there are some parts that are slightly non-round or have flats or other features, requiring a high-precision C-axis to grind non-round components. Again, the goal is to do all the grinding in one clamping or fixturing for consistent concentricity. Further, some machines are equipped with a B-axis for ID grinding parts with precise external radii. The B-axis makes it easier to get better radii and allows you to interpolate the B-axis while grinding.

Some components, such as core pins, are long and thin and require some type of support—often mounting a steady rest on the grinder to hold the part on the opposite side of where you are grinding. This way the part doesn’t bend. If it bends, it creates a bow in the middle and the result is you are grinding a barrel shape instead of a straight shape. Some of these are fixed steady rests and some are following steady rests, which may be automated. These optional tooling and accessories have to be coordinated with applications engineering to ensure the part being ground is cylindrical and straight.

So, it’s not just the configuration of the machine, but holding the parts and processing the parts. You might have multiple wheels—each doing certain types of features. This ensures a better overall part with superior concentricity because all of the features are ground in one setup.

Naturally, many of these questions will be answered by the requirements of the specific application or applications to be ground. But some of the basics—rigidity, accuracy, repeatability, straightness and the ability to interpolate very accurately—these are required regardless of the application.

In addition, a moldmaker needs to consider the thermal stability of the machine. Coolant, for example. Typically, in grinding precision molds you will need to have a chiller system to make sure the temperature of the coolant remains constant and stable, so that when the machine repeats—going from one process to another or from one wheel to the next—the machine remains stable and unaffected by thermal influences.

Tolerances and Costs

Basically, moldmakers are challenged by very tight tolerances—often in the micron range. Even if what they are making is eventually disposable—such as a plastic water bottle— the tolerances to make that part still have to be very tight and precise—such as extremely tight wall thicknesses, because of the high volume of materials used to produce the end product and the competitiveness of the market segment. Therefore, moldmakers must keep the material costs to a minimum.

Cost is also why the reduction in polishing time is so important. While on the one hand you want to have a superior surface finish for product appearance, on the other hand you want to reduce the amount of time and money spent on polishing. Polishing time has a huge impact on manufacturing costs, simply because most polishing is done by hand.

When referring to multiple features we could be talking about a round feature, or in some cases grinding threads. Mold threads are very precise and typically need to be ground. Some of these threads are external threads—for screw-on tops, for example. In other cases they may be internal threads.

Changing Over

Unlike automotive applications that require in-process gaging and the volumes are very large, in mold manufacturing the volumes are generally much lower, and you may have a family of parts that will require frequent changeover.

When these molds are built they may have many stations. For example, there may be 64 cavities and this then becomes the lot size. Basically, you’re grinding 64 parts, and when that’s done you switch over to a different part—a core pin or hot runner, for example—which requires a new setup and changeover.

An important issue in the mold industry is how fast the machine can be changed over from one size part to another or from one component to another. Flexibility in a cylindrical grinder and the way it’s configured are key aids in the ability to quickly change over the machine. Accessories and options—such as a probe to help set up grinding wheels—will help reduce changeover time and increase grind time.

Mold manufacturers who take the time to educate themselves on cylindrical grinding will reap the benefits of the advantages achieved with cylindrical grinding in their mold manufacturing operations—decreased costs, superior surface finishes and high flexibility.

Related Content

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

Transform Grinding into a CNC-Based Technology

Why is it so difficult to automate the grinding department? A common concern in mold shops is how to make the grinding department resemble the rest of the shop.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More