FAQ

How to Get the Most Out of Carbide Recycling

By choosing the right recycling program, mold manufacturers can help sustain both the environment and their industry.

Read MoreHow to Return Manufacturing Jobs to the U.S.: Experts Give Details at Boothroyd Dewhurst DFMA Forum

The good news is that increasingly savvy manufacturers are able to root out troublesome costs and problems from their products earlier and earlier in a lifecycle that starts even before a computer model is created—and ends with finished automobiles, appliances and other goods.

Read MoreHow to Optimize Your ERP Implementation

Proven methodology for using enterprise resource planning.

Read MoreHow to Maximize your Marketing Budget, Part 1

Part of the challenge of a moldmaker’s capability to attract new customers in today’s market is the stunning reality that most have no formal marketing plan in place, and the vast majority has no Internet marketing established.

Read MoreThe Mold Shop Puzzle: Human Resources, Part 2

Creating Constructive Change: Human Resources, Part 2

Read MoreWhat You Need to Know about Medical Processing Hot Runner Systems

Only when there is an understanding of the material properties can you properly select and operate a hot runner system successfully with medical grade resins

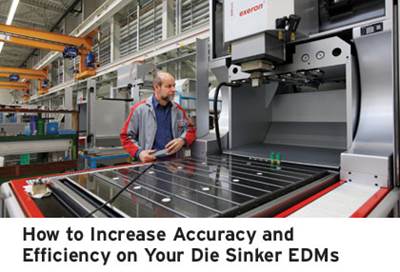

Read MoreHow to Increase Accuracy and Efficiency on Your Die Sinker EDM

A look at reducing the size of the die sinker’s power supply and decreasing the amount of energy consumed during erosion.

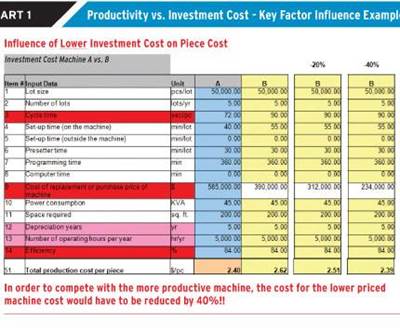

Read MoreHow to Justify New Machine Tool Technology

A look at some of the factors influencing the success of your machining center investment.

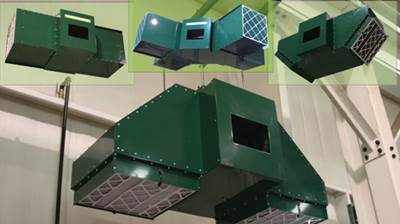

Read MoreHow to Improve Shop Air Quality

Has your company been looking for a solution to indoor air quality problems that are prevalent in the plastics moldmaking industry, but unable to find a cost-effective solution that fits your needs?

Read MoreBenefiting from the Properties of High-Strength Aluminum

When designed and engineered properly, high-strength aluminum has become a mainstream tooling material.

Read More