How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

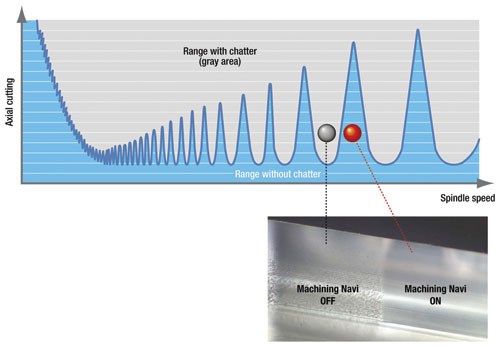

Eliminating chatter is a great way to improve surface finish when performing CNC milling. Control technology detects chatter and automatically adjusts spindle speed to eliminate chatter, thus improving surface finish.

Surface finish problems can be profit killers for today’s mold manufacturer. One of the most common causes is chatter created by vibration in the CNC machine tool cutting process. This can lead to higher costs, delayed deliveries and even lost orders due to poor quality. In addition, vibration can cause uneven tool wear, resulting in poor surface finish, geometry inconsistencies and reduced tool life.

Chatter is caused by the inherent natural frequency of the cutting tool. It can be triggered by many process conditions: toolholding, cutter tooling, part fixturing and machine conditions. Typically, operators try to combat chatter by combining multiple solutions, but some of these may be impossible to implement due to part geometries or machine limitations. Fortunately, there is new technology available today that can eliminate chatter from your cutting processes. Photo Credit, all: Okuma America Corp.

Chatter is caused by the inherent natural frequency of the cutting tool. It can be triggered by many process conditions: toolholding, cutter tooling, part fixturing and machine conditions. Typically, operators try to combat chatter by combining multiple solutions, but some of these may be impossible to implement due to part geometries or machine limitations. Fortunately, there is new technology available today that can eliminate chatter from your cutting processes. Photo Credit, all: Okuma America Corp.Five Basics

Following are some of the techniques commonly used to combat chatter. Use these guidelines to establish a good foundation for optimizing your moldmaking processes.

- The Right Toolholder: Common toolholders (side-lock, double-angle collets and standard ER collets) do not provide the accuracy or stiffness needed for high-performance machining. Better options are toolholder shanks that incorporate face and taper contact to deliver high accuracy and rigidity. This type of holder engages the precision ground face of the spindle with simultaneous contact with the taper, which provides the additional rigidity required, and also aids in damping. All tooling should be evaluated for balancing, which provides improvements in surface finish even at lower RPMs.

- Cutter Tooling Selection: Cutter tooling can greatly influence chatter. Considerations include correct substrate, geometry, coating and length-diameter ratio. Programmers often gravitate to using the largest tool that can fit, but that may not be the ideal tool size. Incorporating multiple tools with variable flute geometries is an effective way to reduce vibrations.

- Proper Workholding: If the part is not properly secured, the part itself can vibrate and induce chatter. There are many excellent systems available to clamp your workpieces. Criteria to look for include high precision, high clamping force, ease of use and flexibility (allowing use across multiple CNC machine tool platforms).

- Machine Maintenance: If you’re trying to hold fine finishes and tight tolerances on a poorly maintained machine, you’ll need to overcome mechanical challenges well beyond the issues listed here. Keep your equipment on a regular maintenance schedule to ensure the best performance.

- Control Solution: The above can correct some causes of chatter, but there are limitations to these methods. The use of new control technology — smart control systems — that navigates processes and eliminates potentials for costly surface finish problems is another method. One such technology is designed to eliminate chatter and take the guesswork out of the trial-and-error process typically used to find the correct spindle speed. This allows the cutting tool and machine tool to continuously operate at the highest performance. It uses a single processor intelligent numerical control and vibration sensors to monitor chatter noise and automatically adjust spindle speed. No longer does an operator need to babysit a cut. With this technology in place, your mold shop can be more profitable and gain a competitive advantage.

Related Content

Partnerships Fuel Moldmaker’s Growth in Technology and Training

Family-owned precision moldmaker, now backed by Heico Companies, combines financial strength with precision expertise in thermoset and thermoplastic manufacturing, apprentice training, advanced automation and comprehensive services.

Read MoreMoldMaking Technology's 30-Under-30 Honors Program: Leadership. Innovation. Giving Back.

We are bringing back this honors program to recognize more young professionals under 30 making an impact in the moldmaking industry.

Read MoreThe Year in Webinars: Top Moldmaking Insights From 2024

Dive back into the year’s most popular webinars that delivered actionable strategies, emerging trends, and expert knowledge to the moldmaking community.

Read MoreMoldmaking Conversations That Made an Impact

The views are in! Explore the episodes that resonated most with our audience, featuring experts in the field, success stories and innovative ideas.

Read MoreRead Next

Chatter Myths: Pieces of the Puzzle in Maximized Machining

In today's moldmaking market, selecting proper parameters of the machining operation to avoid.

Read MoreCut the Chatter - Tooling Tips to Eliminate Vibration in Cavity Milling

By learning how to eliminate vibration in cavity milling operations, a typical moldmaking shop can decrease the wear and tear on its tools, as well as boost its level of productivity.

Read MoreTips for Mitigating Chatter and Vibration

A review of the problems of machine vibration and the strategies and tooling systems that that can stop them.

Read More