Engineer

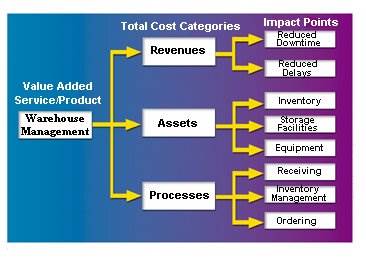

Busy Work No More

Let an expert manage your inventory so that you can concentrate on the craft of moldmaking.

Read MoreA Stellar Hot Runner System

An off-the-shelf hot runner system helps toolmakers streak from order to shooting parts in 18 days.

Read MoreMidwest Mold & Engineering - A Case Study in Data Exchange

By changing CAD systems, one moldmaker was able to reduce the leadtime on some projects from days to a matter of minutes.

Read MoreGetting the Job Done Quicker: What You Need to Know

EDM equipment manufacturers, along with EDM experts, discuss the latest advances to achieve optimum efficiency while maintaining quality.

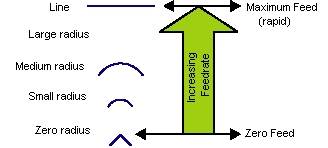

Read MoreBecoming More Accurate With Speed

By adding optimization software to their machining, moldmakers will be able to produce better quality parts with better accuracy.

Read MoreThe Art of Design and Machining

The market is ready to explode as vendors introduce enhancements and upgrades to make the designing and machining of molds and mold components easier and more efficient.

Read MoreVerifying Machining Through Simulation

NC verification technology is one of the most useful computer-aided manufacturing tools available to moldmakers, enabling engineers to simulate the machining process of an NC toolpath in order to detect and eliminate errors before machining takes place.

Read MoreExpanding Business Opportunities With Five-Axis Software

Moving to five-axis machining may seem a daunting maneuver, but with the right software and training, a moldmaker can gain an advantage on the competition.

Read MoreIt's All About the Geometry

Survey respondents from around the world report that while new technology is affecting how they receive and process design data, the transition has been gradual.

Read MoreCAD Brings Advanced Design Tools to Development of New Starbucks Chocolates

CAD designs and rapid prototyping helped ease the design of a new chocolate product for Starbucks - and helped to bring it to market faster.

Read More