Engineer

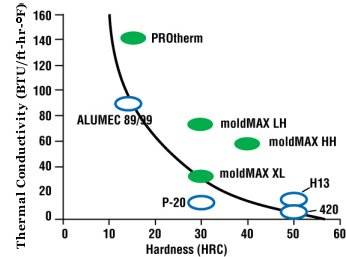

Choosing Thermally Conductive Tooling Materials

By using alternative materials such as aluminum or copper-based alloys, moldmakers can help molders reduce or eliminate some molding problems down the road.

Read MoreFive-Axis Machining Software Offers Speed and Flexibility

Improvements in five-axis machining software are lowering the barrier for adoption by moldmakers.

Read MoreInland Technologies Bucks Trend

A unique mold shop ensures quality, on-time delivery using technology as its key tool.

Read MoreMold Design Using Solid Modeling Techniques

Take advantage of solid modeling to simplify the complexity and reduce the time needed to design molds.

Read MoreSoftware Package Increases Solid Modeling Capabilities

Moldmaker streamlines its operations with new software - cutting design time in half.

Read MoreGetting the Most Bang for Your Buck!

An innovative software package takes you from concept to product more quickly than ever.

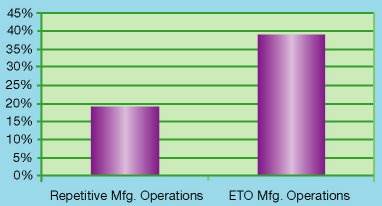

Read MoreCan the Wrong ERP System Cost You Your Job?

More than one-third of all moldmaking manufacturers are custom shops, producing one-of-a-kind, unique products. Ironically, these special engineer-to-order manufacturers are the most vulnerable.

Read MoreEngineering on the Edge

CAD/CAM software enhances reverse engineering in order to create machineable CAD geometry.

Read More7 Key Advantages of Hot Runner Systems

While both hot runner and cold runner systems have their benefits, for design flexibility as well as reduced cycle times and costs, hot runner systems will probably be the better choice.

Read MoreHow to Stay Out of the ERP Trap

A fully integrated ERP software system can mean the difference between profit and loss in the toolroom.

Read More