Engineer

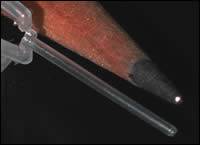

Micromoldmaking: It’s a Small World After All

A great deal of attention needs to be paid to the design and build process—as well as post-moldmaking processes—when making molds for tiny parts.

Read MoreDispelling the Misunderstanding About Small Fittings

It is not always immediately obvious how much effect your choice of pipe tap and water-fitting sizes are having on mold performance.

Read MoreGetting the Most from Your Multi-Axis Machines

The growing importance of simulation and verification of CNC machining processes.

Read MoreA Specialized Mold Design Strategy

Solving complex mold design challenges with specialized CAD software.

Read MoreShop Management Systems Add Value to the Mold Build Process

A new wave of job shop management system tools can help ensure more efficient mold manufacture.

Read MoreMachining Trends for Drilling Coolant Channels in Mold Bases

How to reduce the costs and leadtimes associated with mold base manufacture by using multi-functional machines.

Read MorePackaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

Read MoreOn-Demand Software

What are the pros and cons of on-demand software and which applications are right for on-demand?

Read MoreMold Builders Carve Lean Niche

Commodity-oriented consumer manufacturing left North America, but mold industry survivors are finding strong growth in technical market sectors.

Read MoreDoes Your CAD System Support Design and Validation In One Window?

Implementing one tool that can handle part design, mold design, part structural analysis and mold filling analysis is becoming a necessity for today’s mold shops.

Read More