Machining Trends for Drilling Coolant Channels in Mold Bases

How to reduce the costs and leadtimes associated with mold base manufacture by using multi-functional machines.

Plastic injection molds have been used for years to produce high-volume components ranging from bottle caps to dashboards. The mold bases used for this process have always been high-cost, long leadtime items. One of the main reasons for this is that mold base manufacture requires specialized equipment—such as gundrilling and multiple axis milling machines—which only larger shops were able to afford. At the same time, as much as eight to 10 machine setups can be required for finishing a single mold base, which adds to scheduling difficulties and leadtimes.

Out with the Old

Water channels through a mold base are required to cool the molten plastic, and several steps to drill these bores are required with the traditional mold manufacturing process. After the mold is faced and roughed, spot faces are milled to provide starting areas for the gundrill. The mold base can then be moved to the gundrilling machine.

After the first holes have been drilled, the parts go back to the mill for counter boring and tapping. The bores are plugged so that the high pressure coolant does not spray out of the sides of the part, specifically when the intersecting channels are drilled.

Subsequently, the parts go back to the gundrill to start drilling the next level of intersecting holes. The part can go back and forth several times before all the coolant channels are completed.

In with the New: Multi-Functional Machines

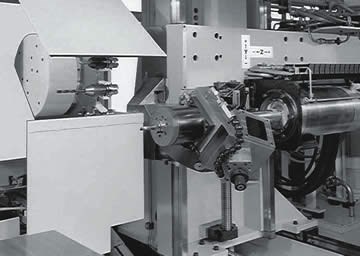

In the past there has been a trend toward the use of multifunctional machines—a combination of conventional machining and gundrilling. The same machines that perform face and pocket milling also execute gundrilling of the coolant channels and counter boring and threading for the plugs. Subsequently, the intersecting holes are gundrilled.

Advantages

Many time-consuming machine re-con-figurations and setups can be eliminated. Often less than one-third of the setup time is needed compared to traditional machining methods. Production is more effective since throughput times and needed floor space can be reduced.

A difficulty in dealing with large, heavy mold bases is repeating their exact location on the machining table during multiple setups. Setup errors occur as a result of the frequent re-clamping of the workpieces, which is required as a result of shifting between machine types.

The modern multi-functional machines allow the integration of measuring probes, which reduces the need for precise locating of the workpieces on the table. The measuring probe touches the workpiece’s edges and the machine controls will automatically execute program offsets.

An added advantage of the multi-functional machine is that most of the machining process will be executed by only one operator and machine programmer. They are fully responsible for the finishing of the complete workpiece, and they know when and where critical process issues come up. As a result, the chance for errors because of a lack of communication or sense of ownership has been significantly reduced.

Optimizing Mold Base Design

One way to increase a mold’s efficiency is to increase its cooling capacity; the faster the mold cools down after the plastic has been injected, the faster the next mold cycle can be initiated. When a gundrilling machine has a fixed table and spindle, increased cooling can be achieved by adding more cooling channels and putting them closer to each other. This dramatically increases manufacturing time.

Another way to increase the mold’s cooling capacity is to put the channels closer to the mold’s surface, which can only be achieved by drilling them under compound angles. This would require more complex and numerous setups. As a result, fixturing time would often exceed manufacturing time. Both solutions significantly increase mold cost.

The most recent development of gundrilling/machining centers allows the drilling of compound angle holes, while maintaining one common fixation. The workpiece table can be indexed 360 degrees and the gundrill/milling spindles can be swiveled in relation to the horizontal axis.

As a result, the machine can reach all five exposed faces of the mold and allows true 3-D machining. This development has pushed the design of gundrilling machines to the limit. Not only do machine rigidity and accuracy need to be guaranteed, flexibility and user-friendliness also need to be addressed. This includes automatic changing of the tool and drill bushing, and special process monitoring features. This also allows the operator to be responsible for multiple machines because the machine can run unattended while he programs or set ups another machine.

Disadvantages

One common disadvantage of the multi-functional gundrill has been that the gundrilling spindle is complemented with a secondary milling spindle. The milling spindle is located next to the drilling spindle. As a result, a potential physical interference is caused when drilling under an angle to the mold’s surface. At the same time, the milling spindle cannot be designed with enough rigidity to execute a significant amount of milling work, nor can it operate with large, heavy tools.

An added challenge is that the machine operator needs to make constant program offsets, since the drill point position and the conventional tool are not located at the same place. This increases the risk for errors and machine crashes.

Reduction of Machine Interferences

The manufacturers of the newest generation of multi-functional machines have resolved this issue by combining the two types of spindles. The machines have one common spindle, which can be used for both the gundrilling operation as well as conventional machining. This significantly reduces the risk of the machine unit interfering with the mold, which gives the manufacturer an extra level of machining freedom. It also reduces the risk of machine crashes. By using spindles with NC motors that have intermittent gearing, the spindle rpms and torque ratios can be optimized for both the gundrilling and conventional machining processes.

An additional advantage is that the spindle can become a true axis, which allows the operator to execute tapping without the use of special tap heads. They also can perform special form milling and interpolation thread milling operations. Some of these machines have even been delivered with automatically expandable tooling to execute bottle and form boring operations.

Conclusion

The most recent development of five or more axis, multiple-function gundrilling machines has improved the optimization of mold designs. At the same time, these machines have provided the shop owners a means of reducing cost and leadtimes. The elimination of the need for multiple types of machines reduces the level of required investment, floor space and number of operators. With the added level of flexibility and versatility, the North American mold industry has been handed a new means of competing in a tough marketplace.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreRead Next

Doubling and Quadrupling Machining Speed, Capacity and Output

Vertical machining centers help to achieve the rapid tool production time a medical thermoformer’s customers demand.

Read MoreMolding Success Through Automation

HSM technology helps U.S. moldmaker maintain world-class productivity and business growth.

Read More

.jpg;maxWidth=300;quality=90)