Engineer

RPM International Tool and Die: An International Force

Although not a U.S. company, this moldmaker faces similar challenges as its American counterparts while providing concept-to-completion services for countries around the world.

Read MoreMachining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

Read MoreHow CAD/CAM Is Making a Programmer’s Job Easier

Arming yourself with the appropriate information will help you select the right software to help your shop work smarter not harder.

Read MoreStreamlining Processes with The Right CAD/CAM Package

VISI-Series provides the toolmaker a high level of productivity through its specialized applications, and offers dedicated solutions while eliminating the links between varying software suppliers and the solid-to-surface geometry conversions required by traditional systems.

Read MoreJustification Through Data

Including position analysis in your data collection practices will help you make smarter maintenance and mold design decisions.

Read MoreOpportunities for Mold Shops with Micro Molds and Micro Milling

Learning about the trends and challenges with micro molds and micro milling will help shops maintain their competitive edge.

Read MoreMold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

Read MoreMaintaining a Strong Relationship with Your Hot Runner Supplier

Once your hot runner supplier is chosen, you need to take the proper steps to maintain a mutually beneficial, long-term relationship.

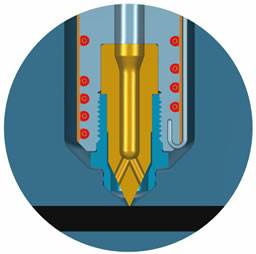

Read MoreSelecting the Right Gating Method for Your Application

Designers may select among four hot runner gating methods, each with its advantages and disadvantages.

Read MoreHow to Exceed the Limits of Your Toolpaths

A moldmaker’s ability to reduce machining time is not limited by his machine tools or cutting tools, but rather by the toolpaths that drive them.

Read More