Shop Management Systems Add Value to the Mold Build Process

A new wave of job shop management system tools can help ensure more efficient mold manufacture.

Share

Job shops estimate, quote, schedule and track tooling throughout the manufacturing process. These busi-ness functions are done with the aid of various software tools, such as (1) Microsoft Excel, Word and Access; CAD viewers, job schedulers and accounting systems; (2) custom in-house systems; or, (3) high-cost “enterprise” systems. Using the right job tracking software tools that can be tailored for your specific methods can add much value to your mold build process, but only if they are easy to implement and support.

Shops Need Quick Answers

Shop managers should know at a glance if they are making money or losing money on a given job, and if they are ahead of schedule or behind. Are you over or under resource capacity? Will additional machines, people or outsourcing be required after your quotes are converted to jobs (sales orders)? Managers must know the present status of all jobs and employees, on the fly during their work-in-progress meetings. And they deserve to have their job shop management system implemented at the same time that it is demonstrated, without the overhead of consultants, support personnel or off-site training.

Complex Systems Are Rarely Cost Effective

Over the past 15 years, many shops bought big enterprise resource planning (ERP) systems hoping that they would solve all their business management problems from estimating through job tracking and accounting. A slew of department managers attended the software demonstrations before choosing their one master system. But of course, the CEO, shop foreman, payroll manager, engineering manager, estimator, scheduler, accountant and shipper each found different systems and features to their liking. So they often settled for one big system that required customization by consultants and support from information technology (IT) people who managed the management system.

In hindsight, it was inevitable that only a few enterprise system modules would ever be implemented at most companies. Consulting and support costs often turned an $18,000 system into an $80,000 system requiring too much system management effort. So in the past, the theoretical benefits derivable from a single integrated system were rarely realized. And over time many shops degenerated back to using a handful of dissimilar software, such as Excel, Word, Access, viewers and schedulers.

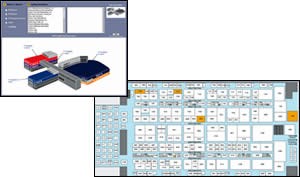

Therefore, at most companies, department managers walk into weekly work-in-progress meetings with armfuls of disassociated papers. They are islands of information. Meeting attendees might not even know if a specific machinist showed up to operate a milling machine unless they phone the shop floor. But if they had an easy to implement and support shop management system, they would be able to see a real-time view of the present staff, machines and jobs’ status—without leaving the conference room.

Easy Shop Systems Make Money

Many shops use Microsoft Excel spreadsheets for estimating and quoting. So an easy-to-implement job shop system should allow for the mapping of existing spreadsheet cells into its integrated database. By doing this, a shop can quickly gain the advantages of an integrated system, such as job tracking, employee time management and capacity planning.

With this method of system implementation during the initial demonstration, companies avoid system start-up costs and can use their new system within hours instead of weeks, months or years. And there will be no need to travel for training courses because the demo can be the initial training. Software sales reps who will not leave a trial version are most likely selling a system that is too complex for the average small to mid-sized shop.

Modularization Is Cost Effective

When selecting a shop management system ask yourself if you must have an immediate “yes” answer to every item on your checklist. If so, you are likely to incur high implementation, training and support costs, and will be unlikely to ever use all of your dream modules. Or do you want a system that can help you make money by performing your required tasks soon after the initial demonstration without exorbitant overhead costs?

Instead of the traditional method of buying an expensive ERP system but using only a little bit of it, consider the starter-set modules of an easy-to-use system and then add on integrated functions as you need them. This will keep your software provider on his toes or else you will not move forward with his additional modules as your business needs evolve.

Estimating and Quoting

Requests for quotes at mold, die and model shops can come fast and often. But the hit-rate percentage for acceptance of your proposals can be in the low single digits. This is because molders seeking tool build quotes can quickly obtain bids from many good sources all around the world. It is not uncommon for a large mold shop to have multiple estimators quoting dozens of different tools every week—just to win a few projects. Therefore, smart shops will standardize and automate their estimating and quotation processes as much as possible.

Along with a request for quotation comes a description of part data in its native CAD system format (or sometimes via a sketch). Because they are at the top of the food chain, production molders call the shots on how they send data to their tool build sources.

For example, they might upload (or e-mail) only native CAD files from Unigraphics, Catia, Solidworks, Pro-E, or less complex DXF or DWG files. The tool shop estimator must be able to read common native CAD formats quickly in order to gain an understanding of the proposed project. Job management software should include full analysis functions for shading, rotating, sectioning, measuring and calculating volumes on native CAD geometry. In other words, the estimator would be better off to have an analyzer as opposed to just a simple viewer.

After analyzing the part, a tool estimate is made and a quotation is produced. This process is made simple by using previously quoted jobs as templates for the new work. For example, the estimator might use standard Windows pull-down tabs to do a search for all previous four- through six-cavity molds in P20 steel for deep parts that were quoted and accepted by customers X, Y and Z between the years 2003 through 2006. Once these quotes pop up, the estimator can edit them with the changed criteria of the new job. And he should be able to easily provide quotation options to his customers in the printed or electronic formats that they demand.

Integrated Job Tracking and Scheduling Are Beneficial

Once a quotation is accepted it is turned into a job (sales order) to be scheduled—making manual scheduling boards a thing of the past. And since a good shop management system is integrated in real time, one can create what-if scenarios with respect to their company’s resource capacities—before or after winning new tooling orders.

After all of the components of a tool are scheduled, real-time tracking through your shop (and outside suppliers) is accomplished. Your personnel can use touch-screens or scanners to input their start and end times on jobs as they pass through various departments By doing this, management knows where each component is and whether the company is ahead of plan or behind.

Start Small, Grow as Needed, and Manage for Profits

Legions of ERP sales reps had some good theoretical ideas throughout the past 15 years, but they had the wrong method of implementation at unreasonable costs. They were selling expensive enterprise systems with the goal of managing all company data. And they tried to get all departments up and running a common system in one fell swoop by relying on consultants and IT people. But they often failed to prove the value of any individual system module during a fair evaluation process.

However, a new wave of shop management systems is upon us. And it is not just a re-packaging of existing enterprise systems. New systems are being built from the ground up based upon the experience gained during the first wave of ERP. The new job shop management systems can grow into complete enterprise systems cost effectively, one bite at a time, as company demands require.

They are easy to implement during the demo stage and can show a return on investment in a few months. And since they support standard products and interfaces, they can be managed without expensive IT personnel. Yet they offer integrated modules so various departments can gain the benefits of a common database system at a reasonable cost.

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreTake Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreRead Next

Can the Wrong ERP System Cost You Your Job?

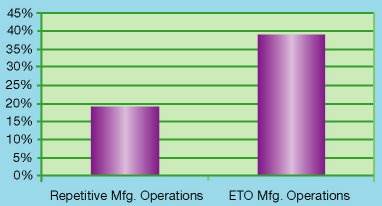

More than one-third of all moldmaking manufacturers are custom shops, producing one-of-a-kind, unique products. Ironically, these special engineer-to-order manufacturers are the most vulnerable.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)