Engineer

Video: CT Scanning for Mold Inspection

Moldmaker NyproMold describes its experience using computed tomography (CT) scanning to validate precise injection molds.

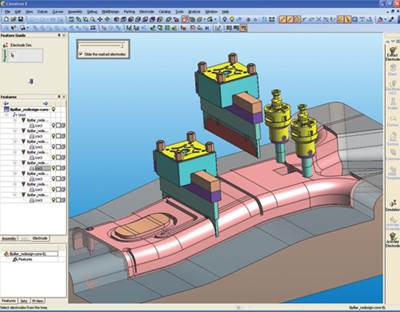

WatchHow to Reduce EDM Setup from Hours to Minutes

The right software helps automate EDM setup and avoid EDM programming errors.

Read MoreCAD/CAM Package Tackles Surfaces/Shapes Accurately

“We don’t just design a part, we manufacture it, so it is important to us to take it all the way through the process with the same software.”

Read MoreNC Simulation Software Verifies Machining Paths—A Critical Step in the Build Process

“VERICUT facilitates our goal of eliminating the need for rework (welding, for example)—improving quality and repeatability, and saving MGS and our customers time and money.”

Read MoreFeature-Based CAM Software Helps Solves Problems

For moldmakers considering jumping into aerospace work, you may be interested in the success story of one tool and die shop using feature-based CAM with Boeing Aircraft.

Read MoreMaking the Jump to Five-Axis Machining Easier

Recent CAM software advances make five-axis machining easier than before.

Read MoreThe Real Cause of Multi-Cavity Mold Imbalances

A lesson on shear induced melt variations ends some confusion regarding balancing runner systems for multi-cavity molds.

Read MoreInjection Molding Analysis Ahead of Tool Production Removes Guesswork From Mold Manufacture

Patented injection molding analysis ahead of tool production, ensures that a number of components in a water powered rock drill are manufactured to the degree of absolute precision required by mining operations around the world.

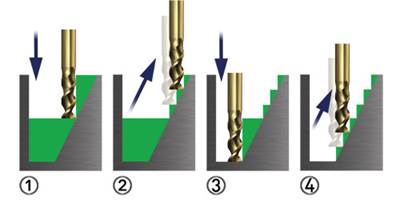

Read MoreHow to Lengthen Tool Life with CAM Software Moves

Long tool life is a combination of three elements: the tooling used the way it’s designed to be used; the holder to contain that tool as rigidly as possible; and how the programming software is applied

Read MoreSoftware Streamlines Complex CAD Design

Understanding its success in the market, Caprock kept its focus on the design process and, in 2011, decided to upgrade its CAD tools to Solid Edge® software from Siemens PLM Software (Plano, TX).

Read More