CAD/CAM Package Tackles Surfaces/Shapes Accurately

“We don’t just design a part, we manufacture it, so it is important to us to take it all the way through the process with the same software.”

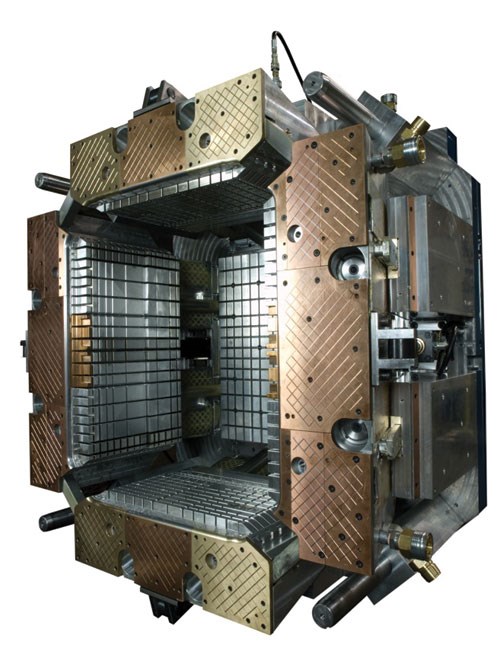

Dayton, OH-based Minco Group—in business for more than 50 years—is a full service mold manufacturer in a range of markets like automotive, medical, consumer products, sporting goods and electrical. A focus on working with complex surfaces and shapes led the company to use NX Mold Design and NX CAM from Siemens PLM Software (Plano, TX).

According to Minco Engineering Manager Jim Sutton, the company prides itself on the quality of tools it takes to press. “We use NX to maintain that quality,” Sutton affirms. “When a customer comes to us with a concept sketch that he wants us to mold and manufacture, we can take the napkin sketch and turn it into a real product with NX. NX gives us the tools to engineer our designs upfront—whether it is product design or tool design. We want to make sure we go through all aspects of the toll and part early on in the process. By doing that we know that when we start cutting chips we are actually cutting what we want, we are not duplicating efforts so it is important for us to maintain that accuracy during the entire process and that is what NX gives us.”

NX is a strong modeler where the designer can bring in data from multiple sources and manipulate complex data easier because of the software’s ability to deal with explicit, hybrid or fully featured models, Sutton adds. “We are not limited by the software in order to develop our product,” he comments.

Minco Group Designer Bryan Lewis points out that the software’s synchronous technology allows the designer to manipulate geometry with ease. “You can go in there and remove or clean faces and simplify bodies without having to worry about parameters,” Lewis explains, “and you can just go in there and change size. That is a mold wizard component. On a recent project, we dropped that in and it automatically knew to hook into the ejector plates. All that we did was put the part area on it by wave linking in the part geometry into the lifter file and trimming it off. If we ever update that part, that lifter will update automatically.”

Then, that master model propagates through the tool design into programming where the tool design will go and update the model, Sutton continues. The programming department can then go in and update toolpaths and data. “This ensures we maintain accuracy through the entire assembly, knowing that the finished part out of the mold will be what the customer initially sent us,” Sutton states.

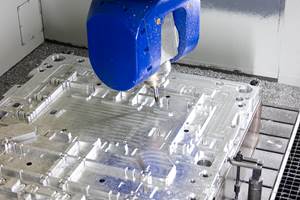

Minco can program 100 percent of the model using the CAM software in NX and then do all of its trode modeling through NX through to the finished product, notes Mike Shafer, CNC Manager. “The master model is very important because everyone is on the same part at the same time using the same model,” he emphasizes. “Everyone is looking at the same thing, all of the time. Everyone knows how to dimension and verify data; you don’t have to teach three or four different softwares. With everyone synchronized on the same software, everyone can help each other. Since everyone wants to save time and money, we implement high speed machining whenever possible, small and light cuts at fast feedrates. NX has several options that you can adjust your paths accordingly that will turn the corners and actually creates a much smoother path. It doesn’t have the jerkiness of the machine.”

CNC Department Supervisor Ed Draper also speaks to the quality of NX. “The finish cut requires no polish,” he says. “Without it, we wouldn’t be in business, pure and simple. If you are not cutting fast you are not making money. If you really wan to cut a true part and cut it accurately, you better have it all today because the pricing isn’t there anymore. It’s a world market and it’s serious business.”

In conclusion, Minco Vice President Joe Kavalauskas notes that NX is vital to Minco’s operations because it is an integrated product. “We don’t just design a part, we manufacture it, so it is important to us to take it all the way through the process with the same software.”

Related Content

CT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

Read MoreTrue Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreSpeed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreRead Next

Software Streamlines Complex CAD Design

Understanding its success in the market, Caprock kept its focus on the design process and, in 2011, decided to upgrade its CAD tools to Solid Edge® software from Siemens PLM Software (Plano, TX).

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More