How to Reduce EDM Setup from Hours to Minutes

The right software helps automate EDM setup and avoid EDM programming errors.

We all know that EDM setup can be extremely time-consuming. Automating the setup process can save valuable time, especially when considering that some tools (especially those with multiple cavities) require dozens or even hundreds of electrodes.

As significant as these time savings can be, the benefits of automating the EDM setup go beyond just speeding up the process. By the time you are ready to burn electrodes, the tool is almost done. Any mistake in the EDM process will put to waste the many hours already invested in the tool. Even more critical, it can jeopardize delivery time. Automating the EDM setup is the best way to avoid any errors in EDM programming and eliminate these risks.

Following are four items to consider when looking for EDM setup software:

1. Integration with CAD and CMM data

Tight integration with CAD data is critical for the accuracy of electrode burn locations and depths, ensuring continuous data consistency from the core and cavity data to the electrode design and to the EDM sinker setup.

Integration with CMM data further guarantees accuracy. Your EDM setup software should be able to self-correct and compensate for any location discrepancies between the design and the actual manufactured tool based on the data received from your CMM software.

2. Complete control over all setup parameters

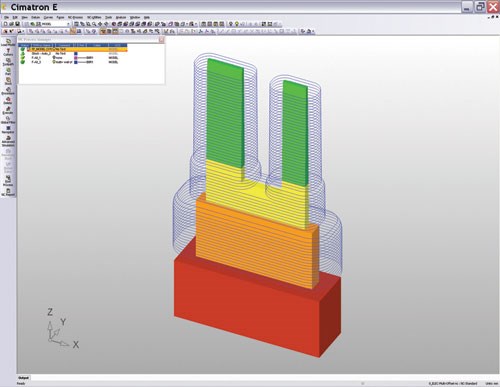

The EDM setup software should provide an easy way to define and control all relevant EDM process data. General parameters displayed and handled through an EDM setup wizard should include electrode identification, material, electrode type (rough, re-rough, finish), orbiting type and size, spark gap, location, burn depth and any other parameters needed based on the specifics of the machine and process used.

In addition, it should give the EDM operator complete control over the burning order of the electrodes, as well as the ability to reverse the order for roughing, pre-finishing, finishing and polishing electrodes. It also should be able to address multisided electrodes, which are commonly used in the industry.

3. Customized to your machine and your application

The ability to customize the EDM setup program for your machines is critical, as each machine has a unique set of parameters that must be specified.

But even the same type of machine is likely to be used differently at different tool shops. For example, in the automotive industry it is common to see one or two-cavity molds, while in electronics and household goods we see molds with as many as 64 cavities. Each of these machines would require a completely different method of EDM setup programming.

4. A picture speaks a thousand words (or numbers)

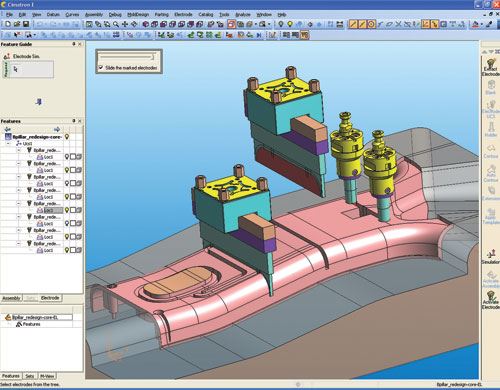

Due to the high sensitivity of getting the electrode location right, EDM operators typically refer to drawings they can cross-reference with the numeric output they receive. Providing operators with access to view-only software instead of the traditional drawings not only saves time and trees, but also allows the operator to better visualize the tool and the electrode locations in 3D.

The bottom line is less time, fewer errors and greater confidence. Automating the tedious task of manually programming EDM sinkers can reduce programming time even for the most complex electrodes to 20 minutes or less. With the right EDM setup software, you can reduce your EDM setup time by as much as 95 percent, eliminate the need for extensive dry runs, and most importantly—never burn an electrode in the wrong place.

Related Content

Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRead Next

Micro-Milling Opportunities and Challenges

An integrated approach to the design and machining of micro-milling components is key for mold manufacturers looking to capitalize on this growing opportunity.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More