Engineer

CAD/CAM Eases the Move to 5-Axis Machining for Moldmaker

Automotive moldmaker that handles molds up to 40 tons says Sescoi’s WorkNC helped ease its introduction to 5-axis machining with its effective global roughing strategies; smooth, powerful finishing; speed and ease; reduction in EDM operations; and, shop floor programming. Today it has four licenses, including two 5-axis for its machining applications.

Read MoreCooling Technology for Cycle Efficiency

A 3D simulation study helps quantify the effects of mold cooling design choices on cycle cooling time, which moldmakers can then use to make smarter design cost versus part production cost decisions at the earliest possible tool design stage.

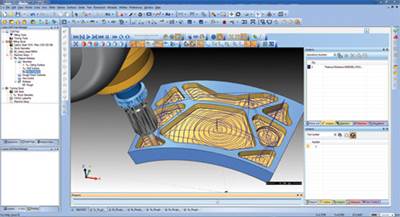

Read MoreCNC Software Delivers 50-Percent Leadtime Reduction for Complex Molds

Industrial Molds considers Delcam’s PowerMILL CNC programming software to be critical to achieving its 8-week average leadtimes.

WatchUsing Simulation to Locate and Size Gates

Considerations and trade-offs when determining proper gate locations with simulation, which helps all stakeholders make a sound decision based on the priorities of the project.

Read MoreThe Benefits of Modular CAD/CAM

Modular CAD/CAM software allows different software functionalities to be available independently of one another.

Read MoreCAD/CAM’s Role in Customer Collaboration

Seven skills—enhanced by the right CAD/CAM solution—that will help you win more business.

Read MoreFrom the Field: Mold Filling Simulation Verifies and Solves Warp in a Plastic Ice Tote

When Beaumont Technologies was solicited by Erie- based injection molder GeorgeKo Industries to use CAE mold flow simulation to prove its hypothesized solution to a warpage issue, Beaumont eagerly took on the challenge.

Read MoreHow to Move Closer to Unattended, 24/7, Lights Out Machining

A look at why there is more to lights out machining than running unattended.

Read MoreTraining for More Efficient Cold Runner System Design

“The training I received from Beaumont taught me how to evaluate different runner design options for a given mold.”

Read MoreUnique Mold Challenge Showcases Moldmaker as Customer Consultant

Ultimately, the Roembke Mfg. mold was a single-drop cold deck with a standard LSR valve gate design featuring side injection versus back injection for the plastic.

Watch