EDM

EDM to a Shine With Silicon Powder EDM

A dual-tank, silicon powder process makes it possible to machine most tool steels to a highly reflective surface finish.

Read MoreSub-harmonic Stress Relief Improves Mold Quality

The quality of the mold lies mostly beneath the surface of the steel. By using sub-harmonic stress relief, moldmakers can improve mold quality - enhancing machine stability, long-term shape stabilization and the mold's resistance to cracking in service.

Read MoreEDM and Automation: The Present is the Future

By automating its EDM department, F&S Tool has been able to increase sales by 50 percent.

Read MoreGetting the Job Done Quicker: What You Need to Know

EDM equipment manufacturers, along with EDM experts, discuss the latest advances to achieve optimum efficiency while maintaining quality.

Read MoreSpecializing in Success

The members of MoldMaking Technology's Editorial Advisory Board express their views on the benefits of specialization to a moldmaker.

Read MoreOperator Training - Is Formal Training Really That Important?

Often, with a new machine acquisition, there are questions about the validity or necessity for formal, off-site, classroom operator training.

Read MoreThe Need for Speed

The trend for higher speeds in machining technology has moldmakers scrambling for the cash to purchase this equipment and the subsequent training to bring them "up to speed".

Read MoreThree Steps to a Diamond Finish

Ultrasonic profilers can be a great time saver. One veteran polisher recounts his step-by-step procedures and thoughts as he tackles one of the tool and die industry's toughest problems - intricate rib work combined with an impossibly short delivery time

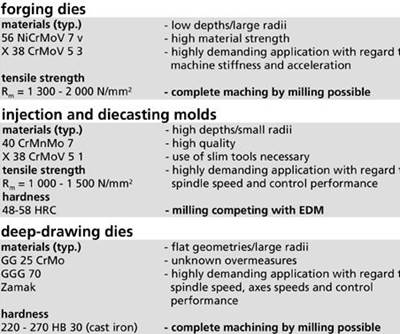

Read MoreTo Mill or to EDM - That Is The Question

Moldmakers are under constant pressure to cut costs and production time. Determining whether high-speed milling or EDM'ing - or perhaps a combination of both - is the best option may be what makes or breaks a job.

Read MoreThe EDM Forecast: Sunny Skies

Despite the growing popularity of alternative technologies, new trends in EDM automation and product efficiencies guarantee its continued use well into the new millennium.

Read More