The Role of Graphite in a Quality EDM Finish

While many moldmakers believe that they can get away with lower-grade graphite if they have a quality EDM machine, in reality, the quality of graphite plays a much larger role in achieving the right EDM finish.

Manufacturers of consumer products that require short production cycles for their new products push moldmakers to decrease the time it takes to build molds. For these manufacturers, any timesavings counts, as many of these products - such as cell phones - have a short life cycle. However, due to increasing competitiveness from foreign moldmakers, U.S. mold shops are trying to reduce production costs as well as leadtimes. How well shops manage their production costs while maintaining quality can give them a competitive edge.

In the early days of plastic injection molding, all molds were polished. Polishing was necessary to allow the plastic part to release from the mold. This required a very fine finish; therefore, the plastic parts would have a smooth, shiny finish. As plastic technology evolved, however, plastics were formulated so that parts could be released quickly from a textured mold as well. Now these new plastic formulas, coupled with a sophisticated EDM, allow the operator to specify the desired surface finish of the mold, and finishes produced by programmed settings can be duplicated from mold to mold. Previously, the only way to produce identical finishes was by etching the molds.

The surface finish of the cavity is an area where there is opportunity to save time and reduce costs while still delivering a quality mold. Advances in technology make it possible to eliminate steps in cavity production. Good EDM finishes can be achieved on the machine, thus eliminating or reducing the need for traditional mold polishing or texturing. Newer plastics don't require a polished surface for the molded part to release from the mold. Technology, combined with consumer preference or acceptance of lightly textured plastic parts, has increased the use of EDM finish.

Producing a Quality EDM Finish

A mold with a good EDM finish is ready to use right out of the machine (tank-to-part technology), while a mold that needs to be etched or polished to get the desired finish requires extra steps that increase cost and extend production time. An EDM finish on a mold can provide the same appearance on the molded part as a more expensive etched mold. Due to the geometry of the cavity, there may be areas that need polishing for quick release, better fit or as part of the product design. Since the mold etching and polishing are often outsourced, extra scheduling, coordination and cost are required. If this operation is performed at multiple locations, there is an increased risk that the textures will be mismatched.

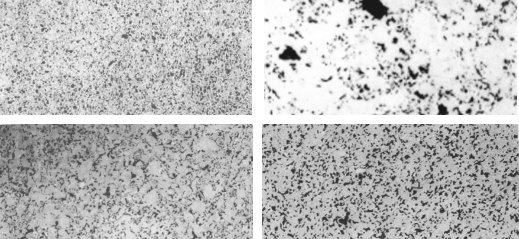

In the etch process, all of the EDM finish must be removed before the cavity can be etched. Even though this finish will be removed, it is important that the cavity has a quality surface and that enough stock remains to allow the polisher to obtain a fine finish. Knowing this process, some production people believe that the grade of graphite is not important, so they try to cut costs by selecting graphite based on price rather than selecting the appropriate grade of graphite based on application. But choosing a grade of graphite that produces a poor finish increases both the polishing time and the cost of the job (see Figure 1).

For example, graphite with poor grain structure allows large grains to fall out of the electrode. Because the working gap is narrow during the finishing operation, these large grains get trapped in the gap, causing a secondary discharge that results in pinholes in the cavity. The working gap can be opened up with higher voltage settings to allow small grains to escape the gap, but this leads to slower performance.

Since imperfections in the cavity - including pits or pinholes created during the EDM process - must be removed, the additional polishing necessary to remove blemishes that extend below the surface may remove too much stock, causing rework (welding and reburning) or remake of the cavity. Etching adds time and cost to the job when a good EDM finish on the cavity can provide the same appearance on the molded part.

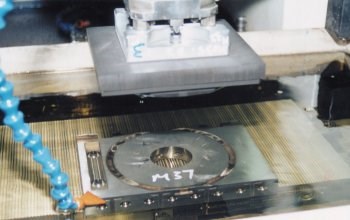

Mold polishing is a very skilled operation because too much polishing can create a cavity that is out of spec. Whether the polishing is to be done by hand or by mechanical means, the same care that enough metal remains for the polishing operation to produce a blemish-free EDM surface must be taken, thus the quality of the cavity as it comes out of the EDM machine is very important to the polisher. Ideally, a fine finish would be reached on the machine, requiring only minimal hand polishing. Under some conditions, the finishing cycle may be lengthy, but due to critical dimensions, it is the best approach. Sharp corners and thin, deep ribs may be impossible to polish; therefore it is important that a good surface finish is obtained in the tank (see Figure 2).

Some EDMs will produce a mirror finish using diffused discharge machining technology (powder additive) that eliminates the need for hand polishing. This technology requires a quality graphite electrode (see Figure 3).

In theory, technical advances allow EDM cavities to have a specified surface finish, including a mirror finish right out of the tank. In practice, the electrode material is the key to achieving this performance. For example, ultrafine graphites with their small grain size, high strength and uniform microstructure will resist wear and particle loss to produce quality surface finishes in less time than graphites with low strength and poor microstructure.

Pitfalls of Graphite Selection by Price

The machined, natural EDM finish is the surface that the EDM process leaves on the metal at the end of the finishing cycle. The finishing cycle puts the most stress on the graphite electrode. Finish settings are high frequency cycles with more sparks, or discharges, per second due to the short on and off times required to remove a small volume of work metal in order to create a smooth surface finish in the cavity. The cavity surface will reflect the quality of the electrode material used to finish the cavity. If the structure of the graphite is not capable of producing the specified surface finish, the machine will continue to run without ever achieving the desired result. When the finishing time becomes excessive, the grade of graphite is likely the problem.

The uniformity of the microstructure (particle size and pore size) of each manufactured graphite grade is different, much the same as the machine technology is different for each manufacturer. As an example, if you select the machine setting for a specific surface finish on two separate brands of equipment, the cavity inevitably will be slightly different. Even on the same machine, if two grades or brands of graphite are used for the electrode, the cavity will be different. Although the cavity will have the correct surface finish, the surface finish reading is an average of the high and low areas, and the textured surface may be very uneven with high spots that are shiny or low areas that will shadow. The uniformity of these areas is critical to the finished plastic and how light reflects off the surface. The shape of the high and low areas is determined by the graphite grade. Graphites with poor microstructure - such as large and irregular shaped particles with weak bonds between the particles - will wear unevenly, causing high and low areas in the cavity.

Another problem is inconsistent surface finish on multiple-cavity jobs. Because graphite grades from different manufacturers will wear differently, they will produce a different looking finish even though the machine was set to a specific surface finish setting. This is most often seen when molds are produced by different suppliers. Unless the graphite grade is specified, the EDM finish will not be the same on all of the molds (see Figure 4).

Know Your Graphite

Graphite selection is critical to the success of the job. It is important to understand the characteristics and physical properties of the different manufactured brands and grades produced. The various grades should fall within one of the four EDM classifications:

- Angstrofine - Less than one-micron particle size material is used when extremely fine surface finishes are required.

- Ultrafine - Less than five-micron particle size materials are most often used for finishing electrodes.

- Superfine - Six- to 10-micron particle size materials are generally used for speed in larger detailed cavities.

- Fine - 11- to 20-micron particle size materials are used for speed in large cavities.

Materials within these classifications can be expected to have specific performance characteristics consistent with that particular grade. As a precaution, care should be taken when selecting a "house brand" of graphite. It is important to know the original maker and the performance characteristics, as graphite that is sold under a house brand may change from time to time and unexpected results could cause problems.

Using high quality graphite actually can reduce overall production costs. The graphite for the electrode is generally a small portion of the overall cost of the job. The best graphite for the application should allow the cavity to be produced with fewer electrodes due to the graphite's resistance to wear. The reduced wear also means that there will be less debris in the gap for consistent cutting. High quality graphite electrodes can handle more aggressive machine parameters than graphite with poor microstructure. Improved accuracy of the cavity is another benefit. The finishing process is predictable due to the consistency of the graphite from block to block.

Because the grade of graphite is the critical element in the EDM process, it is important to familiarize yourself with the various grades of graphite. Selecting graphite on price alone can result in a pitted or out of tolerance cavity that can cost thousands of dollars in rework costs as well as delay the delivery of the mold. The best grade of graphite for the job will certainly give a shop the competitive advantage over a shop that selects graphite based strictly on price.

Practical Advantages of EDM Finish

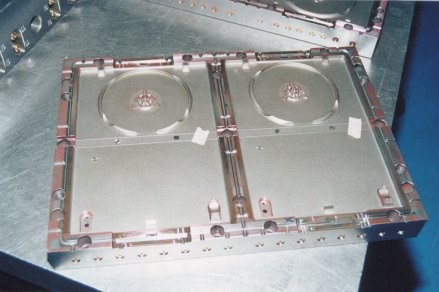

A shop that produces molds for plastic DVD cases excels at jobs that use an EDM finish (see Figure 5). It uses a combination of available machine technologies and quality electrode materials to reduce production time and cost, giving it a competitive advantage over other shops. The shop also is known for quality work. The large, flat surfaces of the case have an even, consistent look. The electrode material is a quality ultrafine graphite material with small grain size and uniform microstucture. The polished surfaces are produced in the tank using diffused discharge machining technology and a premium graphite grade. These cavities are ready to use out of the tank.

Like many other shops trying to cut cost, it first tried using less expensive graphites, thinking the machine technology would compensate and still produce the quality finishes it needed. However, the shop quickly discovered that using the premium graphites actually saved them money on the total job. It was able to reduce its EDM time and achieve the uniform surface finish necessary to produce multiple cavities with the same look and feel that is important to the customers.

Related Content

Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreCollaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More