Design & Mfg. Software

WEBINAR: How Do You Reduce Risk in Plastic Part Design and Manufacturing?

The answer is simulation, of course. In this free on-demand webinar, you will learn how to use upfront simulation to reduce manufacturing risk, design of experiments to make more informed decisions and simulation input to speed machine start up.

Read MoreToolroom Perspective on Micro Molding

Design for manufacturing, or more specifically design for micro molding is critical to this mold manufacturing niche as it presents unique challenges and impacts the tool build.

Read MoreKubotek Updates Kosmos 3D Framework

Building engineering software has been made more streamlined with version 3.0 of Kubotek’s Kosmos 3D Framework, a set of advanced, multi-platform software components.

Read MoreFrom CAM, Cutters and Cooling to Corrosion, Cleaning and Control

A review of the year’s top tips on technologies and strategies to improve moldmaking operations from design to first shot.

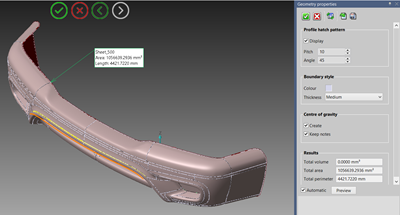

Read MoreMold and Die CAD/CAM Software Offers Productivity Enhancements, Time Savings

Hexagon’s VISI 2021 software offers a range of new and enhanced functionality features under its CAD, Mold, Progress, CAM, Simulation and Wire Function capabilities.

Read MoreMMT Chats: Breaking Down Design, Data, and More

MoldMaking Technology Editorial Director Christina Fuges chats with the program and sales manager for Michael Tool and Mold of Ontario Canada about mold design and data trends.

WatchDecember Technology Roundup: Digital-Only

MMT presents a compilation of digital-only new/proven product content. Hot runners, machining, automation and software categories can be found below.

Read MoreCAM Developer Thrives With IMTS spark Virtual Showroom

DP Technology is hosting live demonstrations, case studies, chats with ESPRIT engineers and more in its booth for the ESPRIT CAM system at IMTS spark.

Read MoreSolidCAD Acquires Autodesk Reseller, AMS 360 Inc.

Marked as SolidCAD’s third acquisition since 2019, the merge serves to support and service manufacturers across Canada with leading-edge CAM training, custom programming solutions and consulting services.

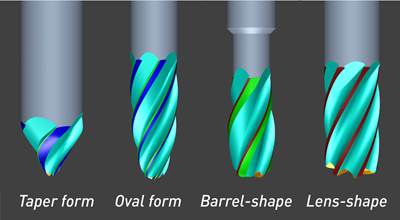

Read MoreToolRoom Software Supports Manufacturing of Complex Endmills

The support of new tool types with ANCA’s upgraded wizard-based BSB software improves productivity, lengthens tool life and makes for faster cycle times.

Watch