Are you a fan of MoldMaking Technology’s monthly print product/service roundups? Then you’ve come to the right place.

In order to acknowledge all of the amazing content we receive on a weekly basis, MMT has compiled all of its digital-only product/service items below for this month to keep your shop engaged in the latest and greatest products that are being offered in the moldmaking industry.

Missing out on the new and proven technologies and services we showcase in our print issues? Head on over here for December’s roundup, or visit the “Magazine” tab.

United Grinding North America’s Blohm PROFIMAT MC high-performance heavy-duty traveling-column grinding center is said to offer the capabilities modern production environments require for various industries and applications. Measuring 94.488" (2,400 mm) wide, the 5-axis, space-saving machine includes an automatic tool changer with up to 24 tools and offers multiple spindle configurations, including an optional horizontal spindle or a stationary or NC-swiveling vertical spindle.

North American supplier of precision machine tools and automation, Methods Machine Tools, Inc., unveils its OKK VB53a vertical machining center (VMC) that is ideally suited for die and mold machining. The high-speed OKK VB53a features a range of features which minimize vibration and maximize accuracy, resulting in superior surface finishes for high-end die and mold applications, and precision parts.

According to the company, in addition to being a highly productive, reliable and operator-friendly VMC solution, the OKK VB53a work space is designed with the operator in mind, offering up to 50% more accessibility than conventional machines.

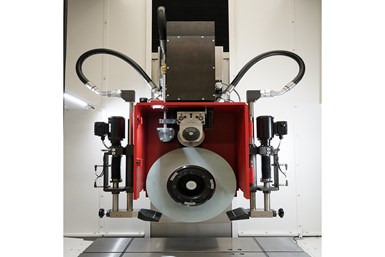

Between the Mägerle MFP 30 5-axis grinding center’s ability to process complex geometries, the machine’s space-saving design and production-flow efficiency, United Grinding’s latest product is ideal for a versatile range of applications.

For highly flexible workpiece processing, the Mägerle MFP 30’s integrated tool changer accommodates multiple types of grinding wheels. These include various tools for milling and drilling operations, as well as measuring probes for quality or workpiece position checks.

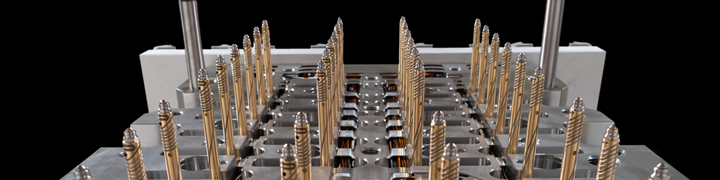

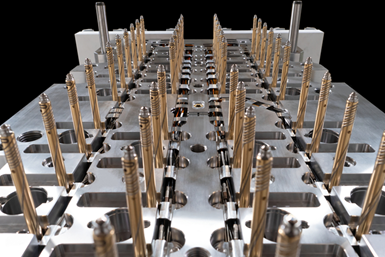

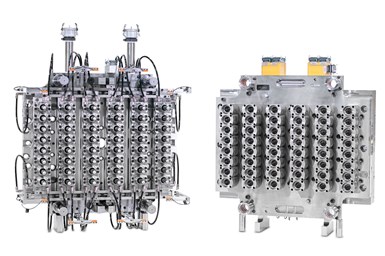

Adding to Husky Injection Molding Systems’ Ultra Helix Valve Gate nozzle lineup, the Ultra Helix 250 T2’s advanced design minimizes wear, provides high gate quality and longevity and was specifically developed to extend the benefits of the Ultra Helix technology to jobs for small part weights and difficult-to-access gate locations.

The Ultra Helix 250 T2 has a 12-mm nozzle bore for direct gating in locations that are said to be not typically achievable with larger nozzles, and pitch spacing down to 15 mm for high cavitation density and a small mold footprint.

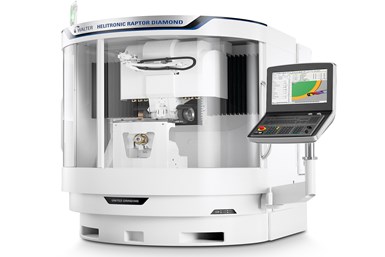

With expert analysis and projections pointing to growth opportunities in applications involving polycrystalline diamond (PCD)-coated cutting tools, United Grinding extends its Walter Helitronic Raptor Diamond for two-in-one grinding and eroding for the production and resharpening of rotationally symmetrical PCD or carbide tools.

United Grinding notes that the machine is particularly well-suited for shops that do not require features such as automatic tool support systems or automatic grinding wheel/electrode changers, but still need a high degree of work-area flexibility for diverse types of tools.

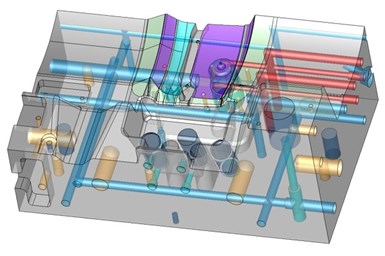

The 2021 release of Kubotek3D’s KeyCreator 3D CAD software, KeyCreator MfgCAD, is designed to maximize productive re-use of CAD data. An efficient and agile manufacturing tool, the software provides improvements to model-based definition (MBD) capabilities, productivity enhancements to various functions and updates to CAD translators.

Marposs (Auburn Hills, Michigan) presents its real-time Remote Testing and Acceptance Service. Marposs is enabling customers to participate in live testing, review and acceptance of their machines/gauges/applications without having to travel, enabling work to continue in an efficient manner while saving time and money.

Tests for North American customers are run at Marposs’ Technology Labs in Auburn Hills, Michigan, Fremont, California, or at HQs in Europe.

The Blohm Profimat XT heavy-duty continuous dress creep feed grinder from United Grinding is said to combine outstanding rigidity and power with fast axis speeds for exceptional grinding productivity, especially on parts that require burr-free results on high depths of cut, all without constant tool replacements.

The machine is available in five sizes, with grinding ranges from 15.75" x 31.5" (400 x 800) to 23.62" x 78.74" (600 x 2000 mm). With a reported spindle power up to 84 hp (62 kW) and 8000 rpm, and grinding wheels up to 20" (500 mm) diameters and 6" (160 mm) widths, the Blohm Profimat XT excels at machining large parts with high stock-removal requirements.

To address machine shops facing capacity shortfalls and labor shortages, robotics company Acieta (Waukesha, Wisconsin) introduces its simple-to-use, flexible collaborative robot (cobot) solution, the FastLOAD CX1000 collaborative expandable robotic cell.

To prevent shop equipment from sitting idle, the FastLOAD CX1000 is mounted on a mobile platform that can be moved easily by a single worker, enabling quicker setup at different machines around the shop. The system is equipped with a FANUC 10KG, 120-volt collaborative robotic arm to master material handling tasks. It can be outfitted with up to three modular carts to handle a wide variety of parts or allow more parts in the queue.

To meet the digitalization challenges of Industry 4.0, United Grinding Digital Solutions is said to enhance manufacturing productivity and production availability while easing process tasks. Built as a modular suite of services, the company presents its Digital Solutions to strengthen manufacturing's transformation to data-driven efficiency with featured solutions including remote service, service monitor, production monitor, customer cockpit and IT security.

Husky Injection Molding Systems highlights the launch of its new NexPET system, a mid-volume PET preform molding solution purpose-built to help producers introduce multiple new applications into the market quickly and cost-effectively, a decision taking into account the increasing consumer demand for more personalized products. Further, NexPET is said to deliver an agile, reliable solution to accommodate niche brands or smaller run SKUs.

Husky’s NexPET system reportedly supports a wider variety of applications, more SKUs, shorter production runs and more frequent design changeovers. The system’s flexible design is suited to meet continuously changing production requirements, while maintaining a Six-Sigma part quality.