Mold and Die CAD/CAM Software Offers Productivity Enhancements, Time Savings

Hexagon’s VISI 2021 software offers a range of new and enhanced functionality features under its CAD, Mold, Progress, CAM, Simulation and Wire Function capabilities.

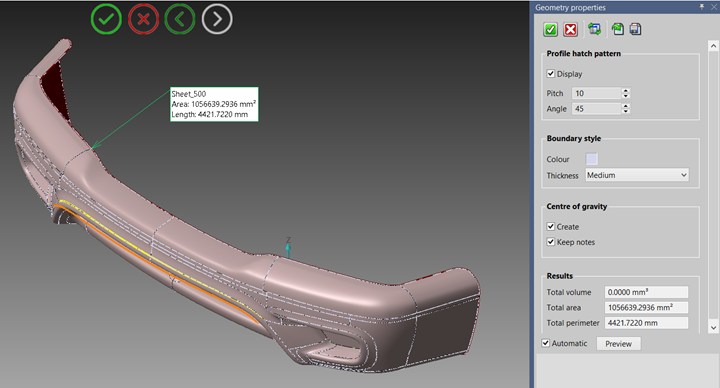

VISI 2021 geometric properties. All photo credit: Hexagon

Hexagon (North Kingstown, Rhode Island) unveils a range of new and enhanced functionality features—including CAD, Mold, Progress, CAM, Simulation and Wire Functions—in VISI 2021, the company’s specialist mold and die CAD/CAM software.

CAD

CAD analysis benefits from a new function which improves the suite of analysis-shading modes. Draft Analysis has been added to the existing Undercut and Accessibility shading, performing an on-the-fly analysis of the draft angle. This uses the same technique as in the undercut mode, says Hexagon, but extended to more ranges. The colors and angular value of each range can be changed by simply clicking on the colors or numeric labels on the graphics toolbar.

Repair functions used in the Repair Invalid Faces of Bodies command are now integrated in the Validate command. It is now also possible to zoom in on any potential issues using the Auto Zoom function.

Developments to the CAD Reverse module enhanced the Reverse and Casting processes. VISI Product Manager Marco Cafasso explains that the scanning operation has been improved with the shaded view, giving better and faster feedback. With Point Scanning, the shaded point cloud is now shown during the scanning operation, giving the operator an immediate view of what has been correctly scanned, and if anything is missing.

Further, new features have been added to increase the probing solution. ‘Leapfrog’ management in Casting has been reviewed to guarantee correct scanning with the laser tracker, for both small and large parts, and Reverse projects now benefit from faster and more precise surface creation. Enhancements to probing during the Reverse process now detect the correct diameter of the part in relation to the position of the probed points. A Circle/Slot probing feature has also been added for probing and designing a circle or slot, giving several options to guarantee the probed element is the correct size and in the correct position.

VISI 2021 Flow: MSC updated mesh libraries.

An additional option has also been added to automatically create a mesh as a scanning result, which Cafasso says is particularly valuable when a quicker, rather than detailed, result is needed. For example, the new Curve probing feature allows the user to probe a curve alongside the part, which can be used to create the relative surfaces, avoiding the need to create a mesh first.

All features relative to surface creation when working on planes, radii and cones from the mesh have been reviewed to save time and enable better quality surfaces during model preparation. According to Hexagon, there is now the ability to define the reference direction or surface of some constraints. For example, while creating the surface, users can select a direction, and then add the constraint type—parallel, perpendicular or concentric.

MOLD—Body to Mold

Additional options to existing commands, along with new items of functionality, make part position management considerably easier, says Hexagon.

With Body to Mold, there is a new option for selecting multiple elements, including solids and surfaces, and moving the selected bodies to the mold position. During part positioning, ‘not uniform scaling values’ can now be defined by the user and the system automatically sets the relative shrinkage data in a special Assembly Manager field.

With Mold to Body, the system allows multiple elements to be selected, including solids and surfaces, and to move the complete mold back into Body position, a valuable feature for operators using CMMs to check tools in the body position, says Cafasso. When browsing mold parts, the system lists those which have been defined as ‘body to mold,’ showing all relevant data, and defined ‘shrinkage’ data can be edited in the ‘reset scale on parts’ function.

PROGRESS—Part Unfolding

To provide a powerful and complete solution to this new unfolding approach, additional features have also been included for flanges and parts with non-linear blends, with an aim to study and modify a part, preserving the links between the different unfolding steps.

The Part Definition feature has been improved, delivering what Hexagon says is better and faster part analysis, identifying the different face types, defining material and setting linear bends for unfolding. Different colors can be set in relation to different neutral-fiber values, providing quick identification for unfolded linear bends and fiber values. After automatically analyzing the part, VISI 2021 can now edit the face recognition, giving a warning description, meaning the user can better understand why an operation has failed, making it easier to decide on a different approach.

A new feature manages flange unfolding on the analyzed part, and shows the result in preview mode, so the operator can evaluate the result and set different parameters while preserving the link with the original part. This automatically recalculates the flanged part, meaning that all linked parts can then be rebuilt in reference to a modification on the original.

CAM Simulation

An interface with Hexagon’s G-code simulator, NCSIMUL Advanced, is offered as a cost option in VISI 2021. Cafasso explains that NCSIMUL manages the complete machining process from the NC program to the machined part. Its capabilities include automatic G-code reprogramming, G-code simulation and cutting-tool management.

Benefits include:

- Read and simulate any G-code and machine tool macros

- Preview toolpath G-code program analysis to detect errors before simulation

- Precise material removal and machine simulation

- Integrated G-code program editor for online modification

- Dimensional analysis

- Analysis and optimization of cutting conditions.

An enhanced waveform algorithm prevents tool damage around pegs (or thin walls) left during the milling process. Those areas are now identified, and the XY step reduced, smoothing the corners. This reduces tool stress, making damage or breakage much less likely.

WIRE

Finally, VISI 2021 introduces a new command, which duplicates an existing wire EDM machine, improving project management for manufacturers using two or more different models from the same machine manufacturer, such as Sodick and Agie.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreHow to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreRead Next

Comparing 3D-Printed Conformal-Cooled Steel Molds to Aluminum Molds

While 3D-printed conformal coolant lines in steel injection molds reduce production costs and improve part quality, aluminum molds can yield similar results faster and at a lower cost.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More