Cutting Tools

Circle Segment Tools and Toolpaths in Action

To take advantage of circle segment cutting tools, the programmer/machinist must generate sophisticated programs that continuously present the tool at a precise angle that is dependent on the slope of surface to be finished and the shape of the tool at any given point in the program.

WatchAchieving Maximum Cutting Tool Life

Getting the most from cutting tools requires high performance from all elements of the entire cutting system.

Read MoreFaster Cornering in Cavity Hogging Boosts Capacity

With a cutter capable of plowing through the corners at full speed, a Michigan moldmaker says it has doubled rough-milling throughput, freeing up machine time for mechanical polishing instead of tedious handwork.

Read MoreMirror Edge Chatter Reduction

Special cutter geometries exist today that are specifically designed to eliminate chatter, regardless of the application.

WatchWhat’s All the Chatter about Aluminum?

Special cutter geometries can virtually eliminate vibration in machining of aluminum molds.

WatchSLIDESHOW: Technology Showcase, Cutting Tools

Need cutting tools? There are so many to choose from it can be almost overwhelming, but here are a few MMT has showcased in recent months just in case you missed them.

Read MoreAnalyze This: Cutting Tool Performance

Examining a cutting tool’s performance values, not just its cost, reveals the true efficiency of machining processes.

WatchHigh Precision in 3 Microns

Low runout is the key to accurate, strong, rigid, vibration-free toolholding.

Read MoreThrowback Thursday: Jig Grinding, EDM or High-Speed Milling?

By examining the advantages, limitations, features and applications jig grinding has compared to EDM and high-speed milling, you will arm yourself with the information you need to make the right decision when it comes to purchasing your next machine tool.

Read MoreMilling in Slow Motion

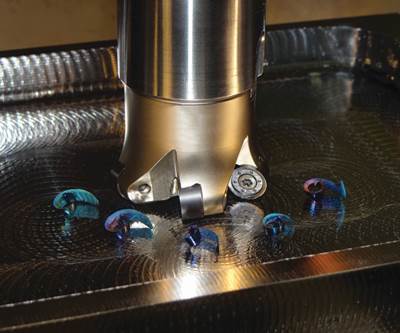

Rough milling operations can take hours on large components and typically remove more than half the raw material by volume. Selecting the proper machining method for the component and machine tool creates a successful and stable system. The use of plunge roughing, commonly referred to as plunge milling, has grown recently as cutting tools that can handle the tough requirements of this machining method have become more readily available.

Watch

.png;maxWidth=300;quality=90)