High Precision in 3 Microns

Low runout is the key to accurate, strong, rigid, vibration-free toolholding.

When it comes to toolholding systems, 3 microns or less of total indicator runout (TIR) is the number to beat. Those that carry the distinction of “high-precision” today will, if properly cleaned and assembled (see sidebar, page 18), provide assembled TIR in the 3- to 5-micron range. However, what really earns toolholding systems their credibility is the ability to repeatedly hold low TIR throughout many years of service, while providing vibration damping, strength and rigidity.

Those qualities are important to mold builders, because a toolholder’s level of accuracy, vibration damping, and strength and rigidity directly impacts workpiece accuracy and surface finish quality. It also affects cutting tool life and the machining process itself.

System Evaluation

Today’s high-precision toolholder systems include collet-type, hydraulic, shrink-fit and mechanical/press-fit varieties. Often, shops will use a mix of systems for different purposes. For example, they may use one type for roughing, and another for finishing or running smaller diameter tools. While each system type offers benefits such as quick tool change-out, the ability to accommodate much smaller sized tooling and the need for reduced tooling inventory, the choice or choices a shop opts for typically boil down to personal preference.

Manufacturers of high-precision toolholding systems suggest a different line of reasoning, however. Many of them contend that shops using multiple systems do so because they have been unable to get the maximum performance from their single most preferred system. When tooling issues arise, these shops will resort to using the tooling with which they are familiar and comfortable.

Instead, these OEMs contend, these shops should determine if the problem is actually solvable with the preferred system they invested in by simply modifying how they use it. This might include, for example, changing parameters to fully experience an improvement, such as peforming high-speed roughing instead of heavy roughing.

Unfortunately, maximizing or tuning in a particular tooling system so that it operates at its full potential can take time that many shops are just unable to devote to the process. What those shops fail to understand, however, is that their high-end, high-productivity machine tool could also be running well under its maximum potential because the toolholding system is holding it back during a particular machining operation.

High-precision toolholding systems, in most instances, will allow shops to not only boost speeds and feeds, and metal-removal rates, but also increase tool life, thanks to the improved TIR, damping and rigidity. Each shop must determine its own particular balance of these conditions, however. Some are willing to step up their material-removal rates even though tool life will suffer, while others will choose to go with longer tool life, especially for long-running mold-finishing operations. (It should be noted that achieving such optimization usually requires the expert assistance of a tooling application specialist.)

As stated earlier, the characteristics of a particular toolholder system that are most important to mold builders are level of accuracy, vibration control, and strength and rigidity, because all three directly impact accuracy of the workpiece and quality of its surface finish.

Accuracy. When evaluating toolholder systems, shops must be mindful of the critical phrase “TIR as assembled.” This means that the tooling manufacturer measured TIR with the entire system and all its components, including the holder, collet (if applicable) and cutting tool, completely assembled.

Many tooling manufacturers can produce all the individual system components well within submicron tolerances, but, when working together, those components could still fail to hold a TIR of 3 microns or better. Plus, when a manufacturer produces a high-precision toolholding system, it does so under several assumptions; two of the more critical ones are that the intended machine tool spindle and cutting tool are equally as precise as the holder system being produced.

Especially for smaller diameter tools, a repeatable TIR of 3 microns or less is basically mandatory for the toolholding system, but achieving this level of precision depends on the OEM’s manufacturing operations. It requires that the toolholder manufacturer machine the system and its components in the submicron range.

In laboratory settings, tooling system researchers discovered that the average runout for typical CAT-40 machine tool spindle pockets was 0.00005 inch or less, and while that is exceptionally low, the TIR can grow to 0.00015 inch at only 2.0 inches out from the spindle face. Add a toolholder with 3-micron TIR and a cutting tool with its couple-of-micron runout into the mix, and end-of-tool runout (in a completely worst-case scenario) can jump to around 6 or 7 microns. What is truly astounding here is that all of the components individually would be well within manufacturing specifications and tolerances.

Vibration control. Mold builders want a toolholding system that will provide superfine finishes to reduce benchwork and ensure the longest cutter life possible. This can be achieved with a holder that effectively dampens vibration, which is why a key requirement of a high-precision toolholder is that it is balanced to prevent vibration.

Most high-precision toolholders are high-speed/factory-balanced so that customers don’t have to use a balancing system every time they prepare to use a cutting tool. Some tooling systems even go beyond factory standards and allow for even finer balancing through the addition of balancing rings that adjust the cutting tool to the specific application at hand.

Other systems use setscrews on the outside of the holder that can be adjusted to balance the holder. However, if vibration causes the screw to come loose during operation, the holder is immediately thrown out of balance and there is the risk of the screw becoming a projectile flying around the inside of a machine.

In addition to being finely balanced, vibration damping of the system is critical. Unlike single-component toolholding systems (shrink-fit), high-precision mechanical/press-fit systems reduce vibration by the fact that their assembly components are each made from a different material, including the collets, holder and cutter. It is this material mix that breaks down the resonant frequencies creating by the cutting of metal to dampen vibration.

Strength and rigidity. Not all high-precision toolholding systems offer both high strength and high rigidity to securely hold tools and prevent them from deflecting. Some systems that tout extremely low TIR are, for the most part, designed for light to moderate cutting loads, such as those typical of finishing operations. Such systems attain their high precision at the sacrifice of holding power.

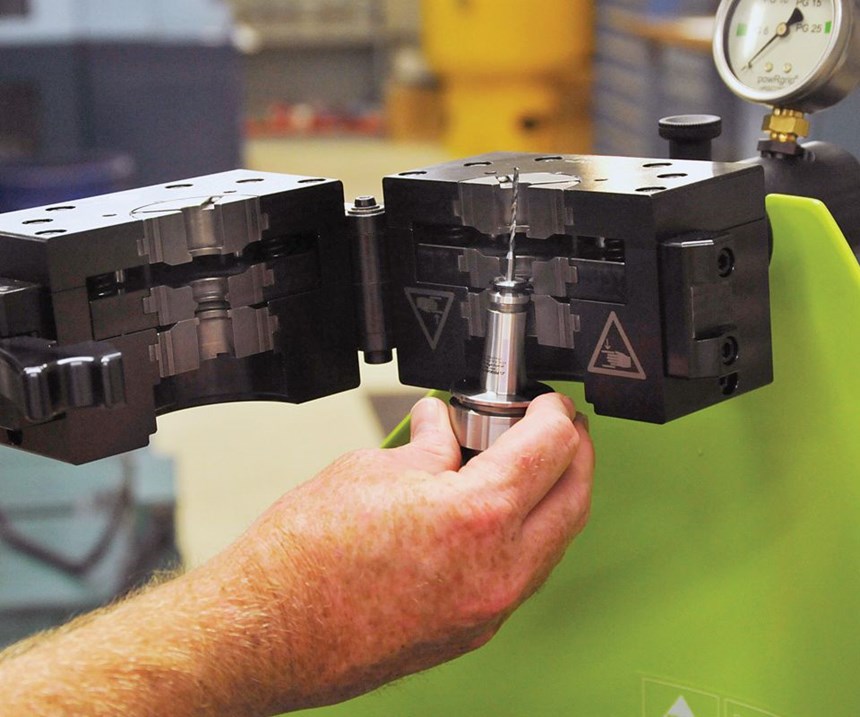

Systems such as mechanical press-fit, on the other hand, provide not only 3-micron TIR, but also high clamping strength and rigidity, which allows the system to run a bit more aggressively for material removal. Also available are various anti-pullout designs for even more aggressive applications such as high-feed roughing.

Only truly advanced, high-end, high-precision toolholding systems can offer a workable balance between both precision (really low TIR) and strong clamping force. In these systems, accuracy, vibration damping, and strength and rigidity combine in a way that allows mold shops to boost productivity and increase competitiveness.

Related Content

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)