Analyze This: Cutting Tool Performance

Examining a cutting tool’s performance values, not just its cost, reveals the true efficiency of machining processes.

Question: “How long should this cutting tool last?” Answer: “How long do you want it to last?”

Answering a question with a question is fair in this case, as it forces a shop to examine its cutting tool expectations and requirements by taking into account the factors impacting the mold machining environment. These factors include cutting tool geometries, coatings, sizes, brands, surface footage, depth of cut, width of cut, feed per tooth, dry or wet machining, horsepower consumption, and rigidity. Manipulating these variables can lead to vastly different outcomes, so a shop’s approach to machining costs is key.

For example, many shops only look at price when selecting their cutting tools and toolholders. This narrow view often results in very poor machine efficiency, which can lead to substantial hidden costs, including longer cycle times, poor tool life, inaccurate profile tolerances and so on. The average mold shop can spend between 2 and 4 percent of its total operating costs on cutting tools and toolholders. If a shop were to find a tool that is half the cost of the one it is currently using, it could theoretically reduce tooling expenses to 1 to 2 percent of operating costs. However, a more expensive tool that can get parts out of the machine twice as fast would double the shop’s potential revenue. Which scenario would you prefer? The answer to this question can be difficult in real-world machining environments, and most shops’ situations fall somewhere in between the two extremes.

Adding Value

Consider these three performance values of the cutting tool to determine machining costs and identify the appropriate machining solution for a shop:

1. The time required for the cutting tool to get parts through the machine.

2. Cutting tool life, as defined by either the number of cutting tools per part or the number of parts per cutting tool.

3. Cost of the cutting tool used.

As you can see, the actual cost of a cutting tool is only one of three factors in the equation, so if that is the only value taken into account, the shop is ignoring the two other essential considerations. To maximize productivity, a shop needs to get parts off the machine as fast as possible at the lowest cutting tool cost with the best possible cutting tool life.

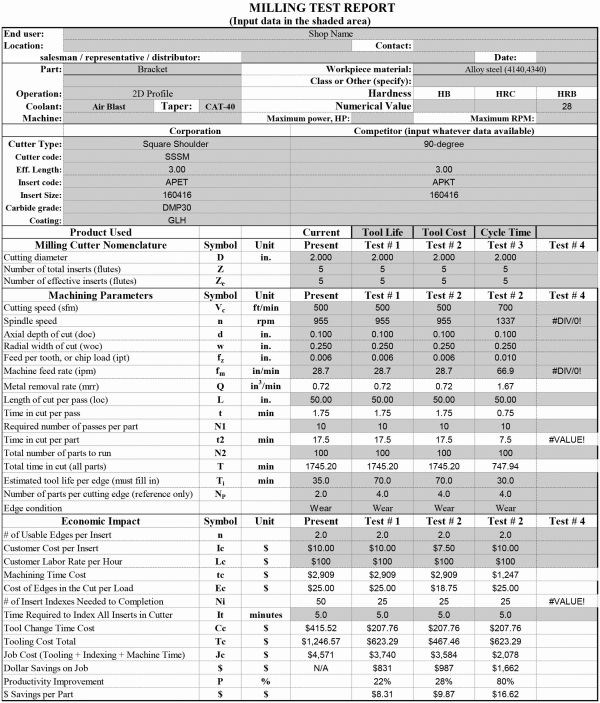

Comparing these key considerations against each other in real-life applications requires some basic math (see chart below). For example, the cost of cutting tool per part plus the shop rate divided by the number of parts per hour. The cost of the cutting tool per part is typically a very small part of the total cost of production. Although using a much less expensive tool initially looks very attractive for reducing part costs, very often that cost savings is only a small part of the total cost reduction. The larger cost savings for most shops comes from getting parts off of the machine more quickly.

In this typical milling test report, Test 1 shows the gain from doubling tool life; Test 2 from doubling tool life and reducing insert cost by 25 percent; and Test 3 from increasing speed and feed while holding tool cost as-is. By far the largest economic gain is shown by the increased productivity resulting from shortened cycle times. However, every situation is different, and gains made by using fewer operators to run more machines, but at slower speed/feed, are more difficult to quantify.

Finding Balance

Increasing output often involves running the cutting tools faster. In milling metals, higher surface footage results in the cutting tool running hotter, which can improve a material’s machinability, as the material flows more easily away from the parent material and across the tool. However, this extra heat will also lower cutting tool life, as it breaks down the hot-hardness of the cutting tool. This often results in thermal cracking or cutting tool deformation. The goal is to find a balance between running longer and running faster.

This balance typically comes down to the application at hand and the preferences of the shop, meaning the shop applies speeds and feeds that achieve a certain number of minutes in the cut, depending on its machining philosophy. For example, does the shop want minimal cycle time and maximum output, or does it emphasize consistency and unmanned machining, sacrificing machining speed for reliability and longer tool life? More specifically, some shops target roughing tool endurance of 15 minutes. If the tool lasts longer, they increase the speeds and feeds until that endurance falls to the 15-minute range. The philosophy here is to get the parts out of the machine as fast as possible. These shops consider cutting tooling costs to be insignificant compared to shop costs such as labor and machine tool time.

Other shops prefer their cutting tools to be as reliable as possible, offering consistency in performance. This is because their machinists are responsible for more than just running one machine or they have a more conservative mindset when it comes to running the shop. Their tools, therefore, run at parameters that allow unmanned operation and the longest tool life possible. This approach is commonly utilized with a lean staff and/or night-time runs. These shops are more likely to target 30 to 60 minutes of tool life, adjusting the speeds and feeds accordingly to achieve this result consistently. Still others believe that aggressive machining is hard on the machine tool and so prefer to maximize machine spindle life.

Adjusting Cutter Costs

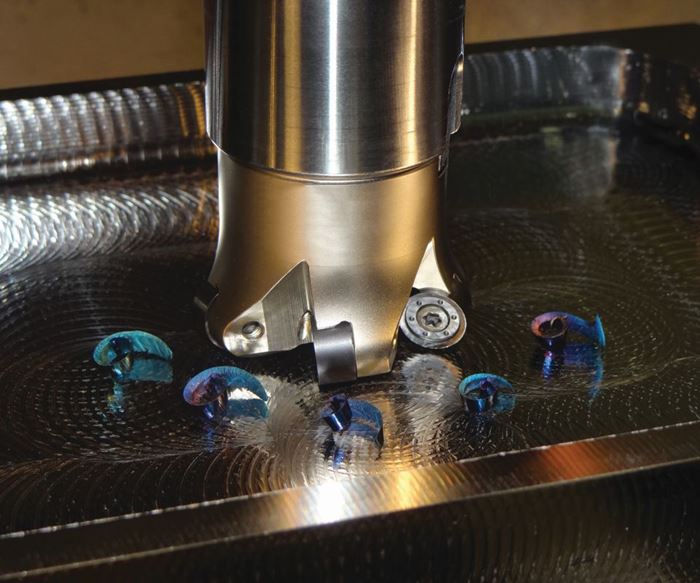

Advances in cutter technology, such as indexable tooling, which has become a popular choice for mold roughing, also impact machining costs. With the indexability of cutting tools comes costs associated with each insert rotation that must be considered. A shop cannot simply calculate the cost per cutting tool.

In addition to the cost of the inserts and how long they will last, it is important to consider the number of edges on each insert and the number of inserts in the cutting tool. A cutting tool that offers four usable edges offers an economic advantage in terms of cost per available edge over a tool that offers only two usable edges, depending on the performance capabilities of the cutting tools. Similarly, a tool with four flutes that can achieve the same metal-removal rate (MRR) and tool life as a tool with six flutes also offers an economic advantage. This is sometimes referred to as cost per rotation, and can be calculated using the following formula: number of inserts in the tool multiplied by insert cost divided by number of usable edges on the insert.

There are many variables to consider when it comes to cutting tool and machining costs, so it is worth taking the time to conduct the in-depth analysis required to determine the proper machining approach and the most appropriate cutting tool for each application.

Related Content

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreHow to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)