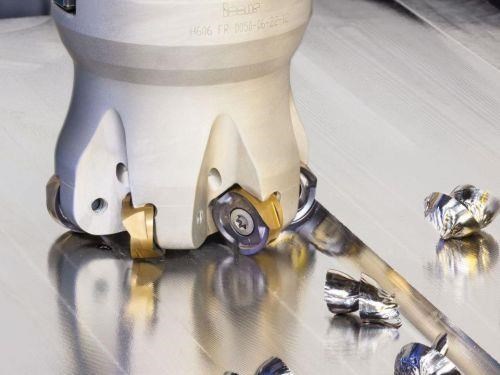

SLIDESHOW: Technology Showcase, Cutting Tools

Need cutting tools? There are so many to choose from it can be almost overwhelming, but here are a few MMT has showcased in recent months just in case you missed them.

Cutting tools are central to almost everything a moldmaker does when building molds. I knew there were many different types of cutting tools, but until I covered cutting tool companies at IMTS this year I didn’t realize that they came in so many different sizes, configurations, and materials, all intended to improve speeds, surface finishes and feed rates. In addition, many are specially designed for a specific kind of machining job and others are manufactured to keep chips cleared from the cutter path while also offering quick-change features that save valuable time. It’s almost overwhelming.

If you're looking for new cutting tools and related products, MMT has covered several of them in recent months. I’m featuring a few in the slideshow above. Be sure to watch for links within the captions that will bring up web pages with more information about each item shown. Happy hunting!

Related Content

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)