Cutting Tools

Tips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

WatchTaking Advantage of Carbide Material for Your Mold Designs

The development of an end mill that can cut 3D features into a carbide material demonstrates how mold manufacturers can reap the benefits of carbide material for their mold designs without a time or cost penalty.

Read MoreTooling Up for Mold Machining

Consider machine tool capability, intended milling techniques, programming, workholding and toolholding during your cutting tool selection process.

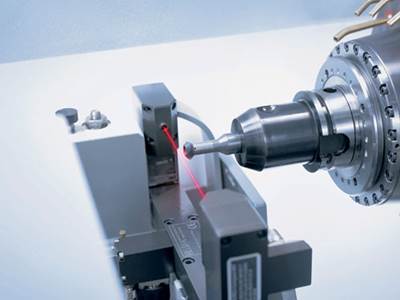

Read MoreHow to Achieve Intelligent, Automated CNC Machining

A review of the benefits of automating CNC machining by measuring and automatically changing the cutting tools as they wear during the machining process, and what a moldmaker should consider before investing in such a technology.

Read MoreButton Cutters Reinvented

Button cutters still offer a competitive edge in many manufacturing processes, despite claims they are being phased out.

Read MoreA New Standard for Roughing in Moldmaking

A look at how to use modern toolholding technology with assurance that the cutting tool will not pull-out and how to increase feeds and speeds during heavy roughing.

Read MoreCutting Tool Refinements Improve Production Levels, Tool Life and Tooling Costs

A roundtable of cutting tool technology suppliers give their input on common cutting tool challenges, trends and solutions for today’s mold manufacturers.

Read MorePrecision Toolholding Optimizes Tire Mold Production

Case Study / Toolholding / Automotive

Read More