Cutting Tools

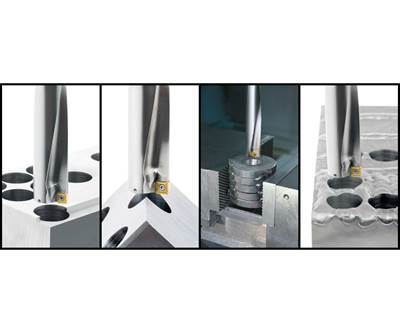

Take the Plunge: Drill vs. Mill

Strategic operation planning and cutting tool system optimization can make plunge roughing a productive, stable choice for high-volume material removal.

Watch2016 Digital "Technology Review and Sourcing Guide" Available

If it's time to upgrade old equipment, try an alternative process, invest in a new strategy or just shop around, MoldMaking Technology’s annual Technology Review and Sourcing Guide is the perfect companion to your decision-making process.

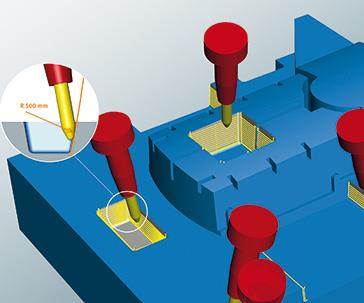

Read MoreBroadening CAM Applications for Barrel Cutters

This alternative cutting tool geometry, along with the right CAM software, can help moldmakers reduce finish-machining times.

Watch5X Tangent Plane Machining

The ball end of a barrel cutter cleaning a corner feature, and then the barrel cutter quickly covers the surface.

WatchBalancing Act

Consider elements of the entire tooling assembly, including the tool, holder and holder components, to optimize productivity.

WatchRough Milling: Speed vs. Power

A look at what works in rough milling applications with solid carbide end mills.

WatchScrap the Tap?

Thread milling is often faster and more accurate than tapping in tough mold applications.

WatchCutter Sets New Standard for Heavy Hogging

A recent roughing application shattered this moldmaker’s expectations about the stability of a large face mill in long-reach contouring operations.

WatchMaximize Hard Milling with Balanced Machining Process Factors

Successful application of high-speed milling of hardened steels requires an understanding of the many factors that influence the entire machining process.

Read MoreRethink Moldmaking with Digital Tool Knowledge

Connecting digitized tool data with CAD/CAM, presetting, production and automated inventory control offers real-world productivity gains.

Read More

.png;maxWidth=300;quality=90)