Cutting Tools

Creating a Balanced Cut

Decrease machine downtime and increase productivity with the right gundrilling tool.

WatchRaising the Speed Limit for Smaller Cutters

An auxiliary electric spindle enables this shop to handle small features and intricate finishing work without investing in a new machining center.

Read MoreUnbalanced Perceptions

You may not realize it, but a balanced toolholder assembly can help you get the most from your machine tools.

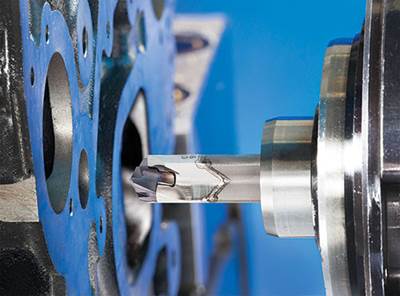

Read MoreChoosing the Right Cutting Tool for Pre-Hard Materials

There are four common tool types to consider for cutting pre-hard materials: ball-end, toroidal, multi-fluted bull-nose and square-end.

Read MoreCarving out Savings at the Front End

Positive-geometry cutting tools help this shop double-down on a key time-saving strategy by reducing machining time on aluminum MUD frame inserts.

WatchRethinking Three-Axis Capabilities

Ballnose cutters don’t necessarily require five-axis machining routines to impart fine surface finishes that don’t require hand polishing.

Read MoreHow to Optimize Moldmaking Milling Operations

The lead angle of your cutter has a dramatic effect on not only the chip that you generate, but also the cutting forces in both the axial and the radial directions.

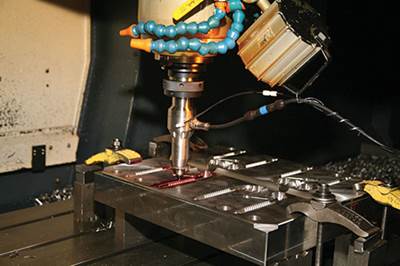

Read MoreSupercharging Rough Machining Performance with Advanced Tooling

What is amazing is that the shop is confident it could run the Seco cutter at 500 ipm if the machine was capable. It is this reason that Build-A-Mold is in the process of acquiring newer, faster equipment.

Read More

.jpg;maxWidth=400;quality=70)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)