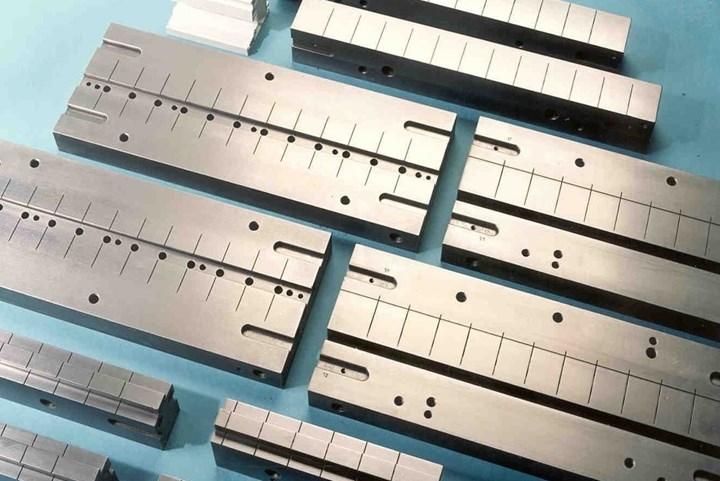

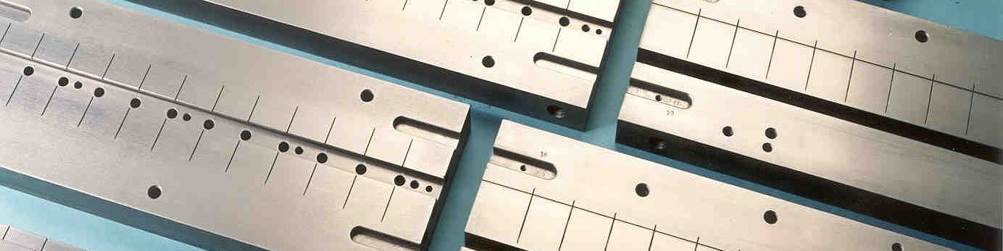

Tool steel selection is one of the many challenges of plastic injection molding because mold builders must consider corrosion and wear resistance, hardness, machinability, polishing ability, and dimensional stability. Photo Credit: Doerrenberg Edelstahl/Tremblay Tool Steels

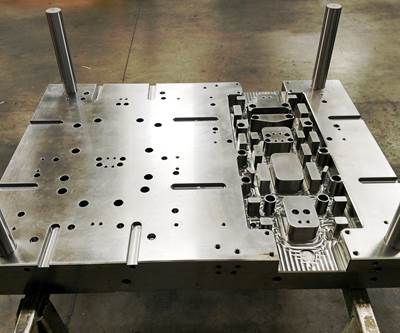

Plastic injection molding has various challenges beginning with tool steel selection, which requires a look at corrosion and wear resistance, hardness, machinability, polishing ability and dimensional stability. Martensitic stainless steels are high alloyed mold materials to consider for meeting these requirements for large mold plates, molds and inserts and plastic pressure dies.

Martensitic stainless tool steels are ideally suited for processing corrosive polymers because of a surface layer that promotes a passivating effect.

Chromium

Steels with a chromium content of at least 12% are generally considered corrosion-resistant. Martensitic tool steels have a high chromium content of 16% and a carbon content between 0.33%-0.38% that provides quenching and tempering during which only tempering carbides appear in the microstructure, leaving behind enough chromium to ensure corrosion resistance.

The resistance to corrosion is based on the formation of surface layers, protecting the metal from further reaction with oxygen. The most effective element is chromium. In combination with oxygen, it forms an oxide layer (chemical configuration: Cr2O3) on the surface, which shows a dense and amorphous structure as the chromium content increases. The formation of this Cr2O3 surface layer of approximately one nanometer promotes passivation, a process that protects the material against surface corrosion and ensures the functionality of the mold.

The Cr2O3 layer can be damaged by mechanical influences such as processing fiberglass-reinforced plastics with filler materials, causing abrasive wear at the oxide layer or chemical influences that include chloride-rich media. Chloride ions remove the oxygen from the layer, reducing the steel’s corrosion resistance. Under oxygen-rich conditions, the layer shows a “self-healing effect,” and the material will be re-passivated.

To create a passivating effect, the chromium must be in a solid solution without forming carbides or nitrides. Limiting the carbon content of stainless steels to 1.2% limits the formation of chromium-rich eutectic carbides and ensures that enough chromium is available for the Cr2O3 surface layer formation. For example, cold-work steel D2 has a chromium content of 12%, but due to a high carbon content of 1.5%, the material cannot resist corrosion. Combining a high amount of chromium and a medium amount of carbon provides both high corrosion and wear resistance.

Molybdenum

Another form of corrosion is pitting. Processing aggressive polymers or using aggressive detergents can create damage at the passivating layer. This chemical attack leads to a point-like corrosion phenomenon caused by removing the oxygen atoms, allowing chloride ions to move into the passivating layer, and preventing it from re-passivating. Active metal dissolution is the consequence, leading to hole formation underneath the Cr2O3 layer. The dissolved metal reacts with the chloride ions of the electrolyte, forming salts which then react with the H2O of the electrolyte via a hydrolysis process. The hydrolysis process increases the proportion of hydrogen ions in the hole ground, causing a decrease in the pH value that makes the environment acidic. So, oxygen diffusion is inhibited in the hole ground, which leads to an accelerated metal dissolution.

Martensitic tool steels have a high chromium content of 16% and a carbon content of 0.33%-0.38% that provides hardening during which only tempering carbides appear in the microstructure, leaving behind enough chromium to ensure corrosion resistance.

Alloying with molybdenum improves resistance to pitting corrosion, as it contributes to stabilizing the passivating Cr2O3 layer. In addition, molybdenum builds into the structure of the layer and strengthens it by preventing the removal of oxygen from the respective layer. Using stainless steels alloyed with molybdenum can also avoid corrosive attacks during mold cleaning, preventing hazardous products from entering the production process.

Machining pre-hardened martensitic tool steels is improved by adding sulfur and manganese to the alloying composition. The formation of manganese sulfides improves chipping during machining which reduces tooling costs.

Sulfur

Modern steel production sets the sulfur content as low as possible. Sulfur is typically an undesirable by-element as it decreases steel toughness. However, in combination with manganese it forms sulfides that improve chipping during machining. Therefore, several pre-hardened, corrosion-resistant mold steels are alloyed with sulfur and manganese. Due to the improved machinability, the overall tooling cost can be reduced.

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRead Next

Use Hybrid AM to Produce Longer-Lasting Multi-Material Molds

A flexible, laser-based hybrid CNC machine makes it practical to produce high-performance molds and dies made from multiple metals.

Read MoreMold Steel Composition Streamlines Moldmaking Process

A mold material’s performance characteristics, like uniform hardness and dimensional stability, enabled Dramco Tool Co. Inc. to build a compression mold faster and more economically.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)