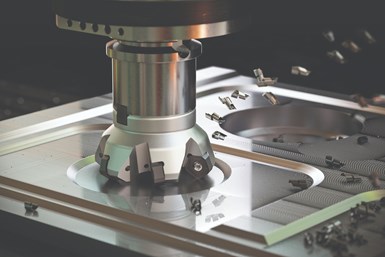

Face Milling Platform Combines Multi-Corner Milling, High Feed Rates

YG-1’s FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

YG-1’s newly introduced FM10 PNMU face milling indexable inserts combine multi-corner face milling performance with high feed capabilities.

The FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

The 36-degree entry angle reportedly generates thinner chips, providing operators higher feed capabilities. The curved cutting ridge and wiper design is engineered to reduce cutting forces and directs these forces axially along the strength of the machining center into the spindle. According to YG-1, these advantages optimize operational stability to provide users superior surface finishes and greater productivity.

YG-1 recommends FM10 PNMU cutters and inserts for milling in steel and cast iron. Now available in the U.S. and Canada, the cutters and inserts can be ordered in diameters of 2" to 4". YG-1 says it is developing an expanded range of diameters as well as extending the line for face milling in stainless and other materials.

Related Content

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.