Build

How to Use Indexable Tooling to Optimize Finishing Operations

High-quality indexable insert end milling systems offer moldmakers considerable cost-advantages for many finishing operations.

Read MoreLeadtime Leader Q&A: Service with a Smile

MoldMaking Technology's 2003 and 2004 Leadtime Leaders reveal the value-added services that keep their shops busy and profitable.

Read MoreMachining Variables Influencing High-Performance Wire EDM

While EDM speeds today are impressive, there are a number of machining variables that influence the machining speed of the wire EDM.

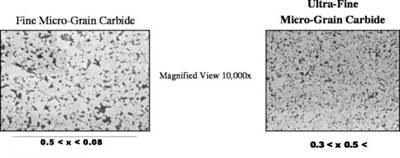

Read MoreAdvanced Cutting Tools Translate To Greater Cost Savings

Increasing initial tooling investments will allow moldmakers take home more profits at the end of the day.

Read MoreStandardized Mold Building Makes Shortened Leadtimes Possible and Profitable

The next level of standardization has allowed moldmakers to rethink their processes and deliver the same high-quality molds, while continuing to succeed and grow.

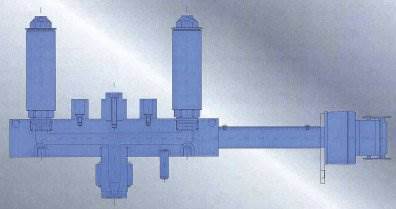

Read MoreUnitized Hot Runner Systems Reduce Errors and Save Time

Unitized and integrated hot runner systems reduce machine downtime for increased production.

Read MoreWentworth Mold: Blowing Away the Competition

Niche marketing, a commitment to technology and short leadtimes equal success for this producer of blow molds-and earns them MoldMaking Technology magazine's 2004 Leadtime Leader award.

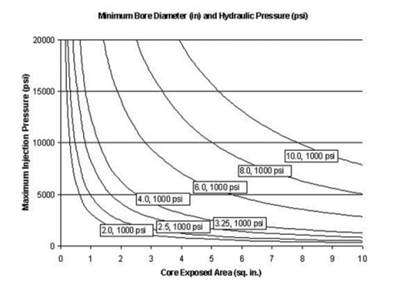

Read MoreQuick Math for Cylinder Calculations

Simple cylinder calculations provide good first look comparisons for proper sizing when moldmakers are considering the most suitable side-action option early in the mold design.

Read MoreM & M Tool and Mold: Niche Moldmaking Yields Results Two Years Running

Complex molds built in tight leadtimes garners this small mold shop MoldMaking Technology's 2004 Leadtime Leader award for the second year in a row.

Read MoreLeadtime Leader Q&A: Planning Ahead

MoldMaking Technology's 2003 Leadtime Leaders shed some light on their plans for the upcoming year.

Read More