Build

Robots Impress at IMTS

I have seen some incredible demonstrations of technology this week, but this live robot at the Siemens booth (E-5010) was really impressive!

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

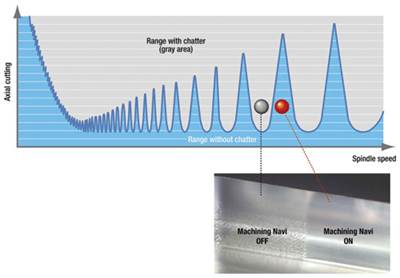

Read MoreEliminate Chatter and Solve Finish Problems

Eliminating chatter is a great way to improve surface finish when performing CNC milling. Okuma's Machining Navi M-i detects chatter and automatically adjusts spindle speed to eliminate chatter, thus improving surface finish. This is a terrific tool for the mold/die industry.

WatchSuccess with Conformal Cooling Using Direct Metal Laser Sintering

Featured project from Phillips Plastics. The design for the DMLS conformal cooling tool insert incorporated channels that were designed to quickly and evenly cool individual cavities within the piece, which would not have been possible with conventional mold technologies. Expectations were reduced cycle time and higher quality parts.

Read MoreAutomation Alley: Recovering Together

Automation Alley’s mission is to grow the innovation cluster of Southeast Michigan. It creates business development opportunities and results for its members and stakeholders who share its values. By helping its members achieve success, Automation Alley aims to increase the quality of life in Michigan.

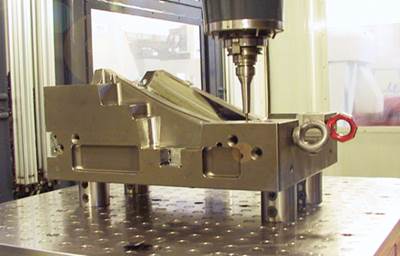

Read MorePlanned Workholding Increases Mold Shop Productivity

Planned workholding using a modular clamping system is a part of the lean approach to world-class mold manufacturing.

Read MoreAdvances in Video Collaboration

How manufacturers can take video collaboration outside of the office and onto the shop floor.

WatchAutomation Advancements Streamline Mold Manufacturing

Implementing new technologies across the entire shop floor improves overall accuracy, productivity and profitability.

Read MoreEquipment Investment Allows Moldmaker to Zero in Medical/Packaging Niches

Tech Mold Inc. (Tempe, AZ)—a manufacturer of high-volume, multi-cavity molds for the medical disposable, packaging (caps and closures) and consumer markets—has invested just under $1,000,000 on new equipment over the past six months. These new capabilities have allowed the company to refocus its efforts in the medical and packaging markets.

Read MoreHow to Navigate New Horizons with Waterjet

Expand capabilities and diversify customer base with waterjet technology.

Read More