Build

Making the Jump to Five-Axis Machining Easier

Recent CAM software advances make five-axis machining easier than before.

Read MoreDiamond-Like Carbon Mold Coatings for Increased Durability

Hardness, wear resistance, deposition temperature and uniformity are the main elements to consider when choosing a coating for mold components.

Read MoreLong-Term Accuracy Meets Moldmaker/Molder’s Machining Needs

“Where you do find time savings is five years or 10 years down the road, when other machines are losing their accuracy, these pieces of equipment are still accurate.”

Read MorePrecision Toolholding Optimizes Tire Mold Production

Case Study / Toolholding / Automotive

Read MoreTechnology Investment Pays Off for New England Moldmaker

For Wepco, the reward of reduced cycle times and increased productivity, which enabled them to book more jobs per week without sacrificing quality, was worth the risk.

Read MoreMachining Centers Allow Moldmaker to Hold Consistent Tolerances/Finishes

“When the difference between success and failure, or profit and loss, can be measured in thousandths of an inch, experience is your most important asset.”

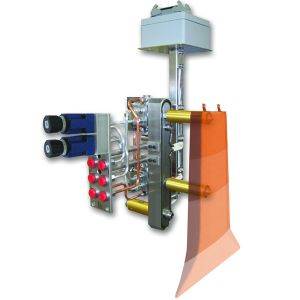

Read MoreF&S Tool Builds 16-Cavity Tool for Co-Injection

IRIS co-injection is achieved via the combination and integration of five key technology elements supplied by Mold-Masters.

Read MoreDon’t Skimp on Tooling If You Want Higher Productivity

To enhance production and your return on investment, choose your tooling based on innovation and productivity.

Read MoreEnd Mills Offer Quality, Accuracy and Affordability

Speed, accuracy and quality are this tool shop's main goals and exchangeable head end mills fulfill those requirements.

Read More