Think Metric

One man builds an argument for designing and building in metric. Part 1

The U.S. is one of the few countries in the world still designing and building molds to inch standards when the global standard for measurement is metric. By using the inch standard our industry is out of sync with the rest of the world (except Liberia and Burma). This became clear early on in my career when I was working on an over-cap for a shaving cream container, whose product drawing was in metric with a 38mm overall diameter. My first thought was to stick with the metric, but as a junior engineer I needed to seek help from a senior designer. One look at the layout provoked a critical question: “What the %#&** is this? Son, we don’t do things like this. You need to convert the part drawing into inch dimensions and then we can talk.”

That was 1990 when there were unlimited tooling opportunities for U.S. mold manufacturers. Advance 23 years and see a mature tooling market whose opportunities must be hard fought. Most U.S. mold manufacturers only look domestically and ignore the European market where much opportunity for new business awaits them. However, a key requirement for selling molds in Europe is fluency in the metric standards. Making the metric change cannot only open your shop up to other markets, but also improve its efficiency. By adopting the global standard we can simplify inventory, increase purchasing power (many metric components are less expensive) and work with simpler numbers with global fits and tolerances.

Establishing the Need for Metric

Fast forward to 2008 and I am now working for a German company with operations in the U.S. When they entered the U.S. market the decision was made to develop and offer standard inch mold bases with its standard leader pin system. The market was there for this product in the nineties and early 2000s, but then came the slowdown of 2007. In 2008 the company decided to no longer offer inch mold base sizes. At this point, I was head of sales and needed to produce a plan to sell metric in an “inch” market.

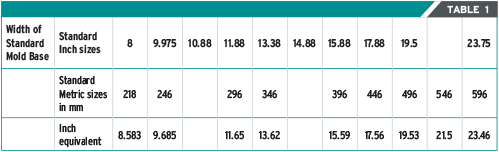

How was I going to accomplish this? I began to examine our U.S. market and noticed that we were selling metric mold bases. Who was purchasing these? It turns out that BMW and other European companies were requesting their mold suppliers design and build their molds to metric standards for consistency. This was a good start, but I was tasked with growing the market, so I created a spreadsheet to compare standard inch sizes with standard metric sizes (see Table 1). This helped illustrate just how close the two systems are—but close is not good enough when it comes to the precision work of moldmaking. Going metric will not require drastic changes; only an understanding of the new sizes and committing to them.

Next, I examined what effect pushing the metric standard would have on the U.S. moldmaking marketplace. I discovered that many U.S. shops are partially working in metric. Some make parts for European customers and build molds that make parts to metric sizes, but the bores and plate sizes are the U.S. inch standard. Other shops are required by customers to use the metric standard, only to convert all the metric sizes to inch sizes for manufacturing.

I also thought if a European company presented a substantial mold package to a major U.S. mold shop—with the stipulation that it be designed and built to metric standards— it would most likely not be turned down. However, I wondered how comfortable this European company would be with a shop that had never used metric standards before, but was all tooled up and ready to go.

Planning and Promoting the Move

With all of this information, I developed a plan to actively promote to moldmakers, with whom I was familiar, the switch to the metric standard: educate the industry on (1) the simplicity of the metric standard, (2) the economic advantages of working with the global standard, and (3) address the fear of change.

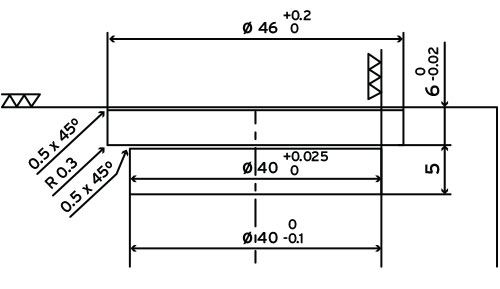

The first group to target was designers addressing the need to understand the standard metric sizes for mold bases, etc. and then move on to pocket and bore sizes, and pitch spacing. Once this was complete, we could work on manufacturing for which we needed to require some metric tools (a 0-25mm micrometer vs a 0 -1”). Then switch the readouts on the machines to mm. Educating management on the metric advantages was next.

I also enlisted the help of a former colleague who also believed in the metric standard and actually conducted training in this realm. He conducted research on the subject of metric in U.S. and discovered that the biggest resistance was fear of change. [An interesting side note, this colleague discovered a book, “The Measure of All Things” by Ken Alder, on the origins of the metric system and its introduction to America, which points out that Thomas Jefferson and John Adams were in France while the metric system was being formulated.]

The economic crisis of 2009 put many plans on hold, including our think metric project. However, as I moved on I remained committed to the effort because I was convinced that it was important for American mold manufacturers to understand the value of working in metric. At this time, I was basically a consultant holding open discussions with several moldmakers.

After several meetings, we reached general agreement on the fact that converting the numbers is easy; shop personnel have easy access to a calculator to convert the metric dimensions to inches before making the part; and, most CNC (all of which are built to metric standards) have a software toggle that can switch the display and input from inches to metric.

The first month will be challenging, and the next two months will be uncomfortable, but then you will wonder why you didn’t make the change sooner.

Breaking Down the Roadblocks

So what are the roadblocks? The answer lies with management. For the metric switch to be successful, management needs to commit to a direction; overcome the fear that mistakes will happen, which will cost the company; and, recognize the potential market in Europe and other metric countries.

At the end of my discussion on metric at this company, the owner stated that he didn’t have an issue with the change, because they were already doing some work in metric, but “if we are going to do this, we need to get the metric gauge blocks and other tools we need, to ensure this happens quickly and accurately.”

Summary

So maybe it’s time your shop considered making the metric change, and see for yourself how it can open new doors of opportunity, improve efficiency, simplify inventory and increase purchasing power. Next month we will hear stories of some mold manufacturers and then review the steps to making the metric switch.

Contributor:

David Frost is manager of Frost Technical Concepts, a company he started to help bring unique, new ideas using leading edge technology to clients he works with in the plastics industry. After earning Bachelors Degree in Mechanical Engineering and completing the course work for a Masters Degree in Manufacturing Engineering, Dave went on to gain more than 20 years of experience in the plastics industry beginning with his post at Tredegar Molded Products as a Project Engineer. From his very first project, he worked on and succeeded with maximizing the productivity of a 96-cavity cap mold. Dave moved on to Crown Cork & Seal where he introduced the first plastic 38mm beverage cap to the market and also worked with mold maintenance and reduced the time required to PM a mold by 8 hours. Dave then moved into hot runner system sales and subsequently mold sales, where he was constantly challenged to find new ideas that would give customers a competitive advantage.

For More Information:

Frost Technical Concepts, LLC.

(413) 329-8630

dave@frosttechnical.com

frosttechnical.com

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

A Collaboration to Put “Collapse” on the Rise

“The idea behind Demo Day was let’s not just talk about the benefits of c-core technology, let’s build a mold so people can see up close the true capabilities of the DT Core as it molds a typical cap.”

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More