Looking for Ways to Reduce Energy Costs?

Then consider areas in the machining processes that unnecessarily consume energy. For example, machining center idling, unnecessary pump rotation and continuous running of peripheral equipment. Managing these areas can save a shop a lot of money. This is the subject of a white paper I came across recently that reveals how shops can achieve significant energy savings using the right CNC control to reduce power consumption during machine operating and waiting times.

Looking for ways to reduce energy costs? Then consider areas in the machining processes that unnecessarily consume energy. For example, machining center idling, unnecessary pump rotation and continuous running of peripheral equipment. Having the ability to manage these costs can save a shop a lot of money. This is the subject of a white paper I came across recently that reveals how shops can achieve significant energy savings by using the right CNC control to reduce power consumption during machine operating and waiting times.

The white paper, published by Okuma America Corporation, titled “Energy-Efficient Machine Tool Technologies, For Any Size Shop,” is available for free download here.

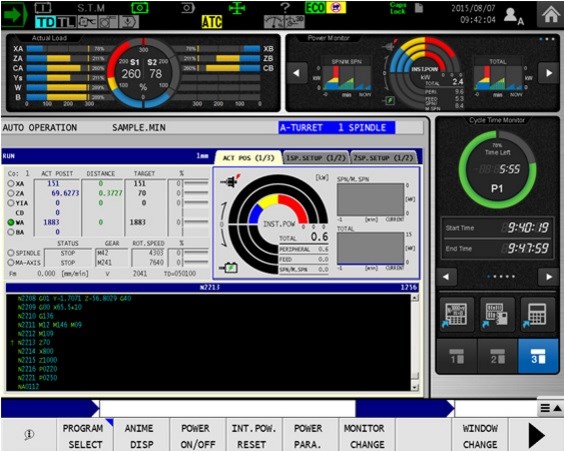

According to the company, this CNC control reduces power consumption through four new intelligent control applications: Idling Stop that stops machine tool idling, Power Monitor that allows operators to see how much energy is being used and saved, an Hydraulics feature that provides accurate machining control at a very low rotation speed and Operation that allows operators to set time limits for peripheral equipment, automatically stopping them after cutting is finished.

What are other ways your shop is reducing energy costs?

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

.jpg;maxWidth=970;quality=90)