Analysis

Strategies for Evaluating, Maintaining Equipment

This year's Leadtime Leader award winner doesn't settle for just any test cut to evaluate a machine's capabilities. Once it does make a purchase, the shop's approach to ensuring those capabilities don't deteriorate is anything but cavalier.

Read MoreTemperature Control Technology Streamlines Sampling

This moldmaker speeds tool tryouts with machine-side systems that combine all needed functionality for temperature and flow-rate testing into a single unit.

Read MoreControl the Process to Drive Profitability

Process control technology boosts productivity and profitability through increased throughput of good parts, reduced inspection time and dependable production schedules.

Read MoreMMT's February Digital Edition Available

This month we bring you features on the benefits of cooling-free valve gate actuators, new mold components to help with molding very small threads and undercuts, strategies for maximizing the life of your inspection equipment, how to improve profitability by properly collaborating with your supply chain and much more.

Read MoreMore Moldmaking Market Data

In addition to the data and analysis Steve Kline Jr. provides each month through his By the Numbers and End Market Report columns, he has much more market research to offer.

Read MoreVideo Tutorial Covers NIMS Testing

This video from the The National Institute for Metalworking Skills offers A-to-Z instructions on each phase of implementing the credentialing process at your training location.

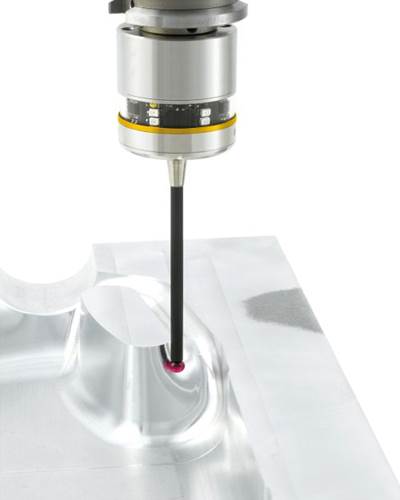

WatchGetting the Most Bang from Your Metrology Buck

These strategies can help maximize the life of your metrology equipment while minimizing the total cost of ownership.

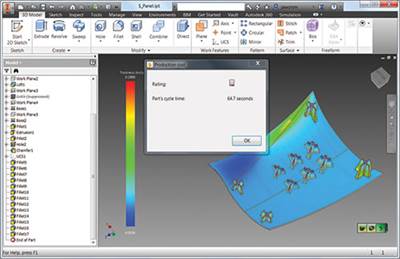

Read MoreMaximize Process Efficiency

Cooling simulation tools can help companies evaluate thermal management early to make informed decisions that will lead to reduced risk downstream.

WatchMMT's November Digital Edition Available

MoldMaking Technology's November issue highlights technology features and shop profiles on inspection/measurement, software, business planning, global market opportunities and mold maintenance and repair.

Read MoreMetrology Molds a Better Bottom Line

Improved accuracy saves time and drives down costs in the moldmaking process.

Read More