Analysis

Throwback Thursday: Rough Milling Applications: Technology and Tips

When it comes to productivity gains in rough milling applications, this article examines how cutting tool technologies and strategies can play a major role and how to measure and choose the right process and solution.

Read MoreMoldMaking Technology's August Digital Edition Available

This month we look at gaining control of five-axis mold machining, the internal valve gate, multi-level inspection, cultivating craftmanship, streamlining shop tracking and management, and much more.

Read MoreThrowback Thursday: Using Industrial CT Scanning to Reduce Preproduction Inspection Costs

For this Throwback Thursday, a look at the analyses that have been found to benefit major automakers, tiered suppliers and moldmakers.

Read MoreMulti-Level Inspection Yields Valuable, Data-Driven Results

Advanced inspection technologies are as central to the operations of Matrix Tooling Inc. as machining.

Read MoreEnhancing the Benefits of Multi-Component Molding Analysis

Automatically generating surface and solid meshes of a part, part insert and mold base calls for a simulation tool for over-molding and insert molding along with a robust pre-processor.

Read MoreMay MMT Digital Edition Available

This month we take a look at how to define mold steel toughness, a new roughing strategy that helps maximize metal removal rates and reduce roughing cycle times, enhanced metrology technologies, electrode material selection, women impacting moldmaking, and much more.

Read MoreApprentice Training - Precision Inspection and Measurement

Here are some basic principles concerning inspection and measurement to take into account when developing your related technical instruction (RTI) plan.

Read MoreLeadtime Leader Q&A: Inspection and Measurement

Moldmaking Technology's 2016 Leadtime Leaders share their views on inspection and measurement.

Read MoreData-Driven Quality Control

Enhanced metrology technologies can help streamline mold scanning and inspection.

Read MoreTest Rig Ensures Mold Cooling Channels Work at Peak Efficiency

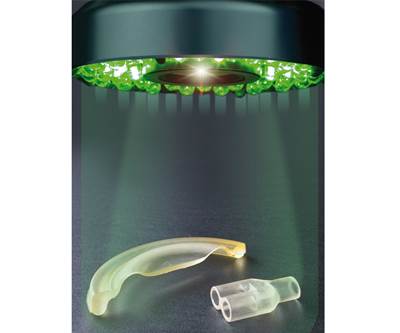

It’s no secret among moldmakers that optimized mold cooling is essential for achieving faster cycle times and flawless, injection-molded parts.

Read More