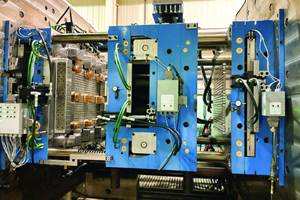

Versatile Mold and Design has the capacity to tackle large projects more efficiently than most, recently completing a 25-tool package within 16 weeks. These high-production molds for the electrical industry were designed and produced on-time. Source | Versatile Mold and Design

Could you tell us about Versatile Mold and Design’s history and current operations?

Robert Heusser, Jr., president, Versatile Mold and Design: We were founded in 1998 by my father and journeyman toolmaker, Robert Heusser Senior. From Connecticut, he had a background working on helicopters at Sikorsky Aircraft and hoped to get into mold design. His extensive knowledge of specialty metals drove him into the tooling space where he started building a network of partnerships in the 1990s. 26years later, I became president of Versatile Mold and Design, working alongside my siblings Frank Heusser, Timothy Heusser and Suzanne Brown who hold leadership positions within the company and have helped to grow the company in a few key capabilities and markets.

In 2024 we chose to join the Heico Family of Companies as we felt it was a unique opportunity to grow the business while keeping the spirit of our father intact. While my father is no longer with us, his vision lives on in the bright future of Versatile Mold and Design.

Versatile operates a 35,000-square-foot manufacturing facility in Rutledge, Georgia, employing 34 people, including three apprentices.

Today, Versatile operates a 35,000-square-foot manufacturing facility in Rutledge, Georgia, employing 34 people, including three apprentices. It also maintain a partner facility in Shenzhen, China. The company offers comprehensive molding services including thermoplastic injection (engineered thermoplastics), thermoset injection, thermoset transfer, thermoset injection/compression and thermoset compression, along with tooling, engineering, finishing and repair and modification capabilities.

What sets Versatile Mold apart in the market?

Heusser, Jr.: Our people. Customers approach us with specific needs, and it is the creativity of our staff that helps co-create the solutions. While the technological aspects are impressive — people enjoy seeing parts and tools on a screen — ultimately, it is the people who bring the steel and plastic to life.

However, when it comes to our capabilities, we have significant expertise in thermoset and thermoplastic molding. As a full-service molding facility, we can support all phases of the molding process, from design to mold sampling and experience with large tooling packages.

Versatile addresses hiring challenges by prioritizing internal training to grow employee skills and advance their careers within our company. Here, an apprentice adds the final touches to a mold.

We can tackle large projects more efficiently than most, recently completing a 25-tool package within 16 weeks. These high-production molds for the electrical industry were designed and produced on-time. Thanks to our advanced onsite laser scanning, we can get molds approved in a timely manner with most first target submissions being 100% dimensionally correct. This cuts approval time in half and enables us to get products to our customers faster than other companies.

Our recent acquisition has also strengthened our position. Being part of The Heico Companies gives us the financial stability and resources of a large organization; while still providing the personalized, responsive service you'd expect from a small business. It enables us to keep making the best tools out there, while having access to and the capabilities of a much larger organization. They offer us the resources to do more large packages, more often.

“Know your customers, know what they want and how we can help them.”

The Heico Companies is a family-owned holding company that manages a diverse portfolio of businesses in manufacturing, construction and industrial services. They have over 9,000 team members worldwide.

How has having offshore partners influenced your operations, particularly regarding lead times and cost-effectiveness?

Heusser, Jr.: International supplier and vendor partnerships are critical. While we would prefer to build all tools domestically, the fact of the matter is that it is not always the most practical option for the customer. We have developed a network of suppliers that follow our design-build standards and specified materials and deliver on schedule. Developing and nurturing these partnerships (both as a supplier and a vendor) and having the right people in place to manage our robust and repeatable processes has been key to our success.

Advanced software and high-speed machining techniques significantly reduce lead times.

How has technology changed your operations recently, including reducing project timelines?

Heusser, Jr.: The technology side of the equation is fascinating and ever-evolving. We use various tools to help automate and make better decisions on design and production. It requires a different skill set and approach to maximize digital solutions for moldmaking, and we are often in a position to learn something new.

For example, we create tooling to develop geometries for customers according to their exact standards from the most basic inputs. We manage measurements internally using various techniques and collaborate with third parties for advanced or non-traditional data collection. We use that data to develop parts, cores/cavities and mold components digitally. Then we make digital edits and quickly create prototype or production-level tooling with iterative changes. We modernized our collaboration methods, implementing cloud-based file sharing for project optimization.

We also integrated advanced software and high-speed machining techniques that have significantly reduced lead times. We invested in WORKNC CAM software to program complex models, which has reduced training and machining time, ensuring our process is at the forefront of technological advancement.

A CNC operator machines ejector plates for a new mold build, as the company prepares to implement lights-out machining to boost efficiency and productivity.

Looking ahead, what are your plans for growth and development?

Heusser, Jr.: The Heico Companies and the Heusser family are enthusiastic about the future. We will maintain our focus on customer service, and we believe that our customer mix will remain similar to what it is today.

Incremental improvement is the name of the game in this business. Achieving continuous operation — 24 hours a day, seven days a week, 365 days a year — is an ambitious goal, but we believe it's attainable. To do that, we must remain diligent in our project planning and scheduling. When a customer requests something overnight, we must find a way to balance their needs with our existing schedule. While it may not always be the most enjoyable position to be in, it is a situation we often encounter.

Customer discussions drive our capital equipment investment. Some of them are very excited about a few new technologies that we are keeping an eye on, including Mantle. In the next three to five years, we plan to move towards lights-out machining to enhance efficiency and productivity and integrating advanced automation and AI to strengthen our market position and solidify our leadership in precision manufacturing.

An advanced onsite laser scanner inspects electrodes to verify draft angles and ensure dimensional accuracy according to the drawing.

“It requires a different skill set and approach to maximize digital solutions for moldmaking, and we are often in a position to learn something new.”

We are considering expanding some of our capabilities in Rutledge and our medical industry presence and increasing our throughput capacity by offering preventative maintenance, refurbishments and new mold builds for medical devices.

We are currently in the process of acquiring our ISO 13485 certification. This involves time-consuming audits, and while we are one of the best tool makers, we are a small team managing a business. Keeping our process documentation updated has helped us remain compliant and has made it easier to pursue new certifications. However, there's always an unexpected challenge during each audit or certification process. The key is to be prepared and honest.

How are you addressing the industry-wide challenge of

Versatile offers thermoplastic injection, thermoset injection, thermoset transfer, thermoset injection/compression and thermoset compression molding.

finding skilled workers?

Heusser, Jr.: Versatile has adopted a two-pronged approach to workforce development. We are addressing hiring challenges by prioritizing internal training, which helps our employees grow their talents and advance their careers within the company. Our focus on this business area has increased as we recognize the importance of keeping engaged and appreciated employees for retention, particularly in our industry. We have also successfully placed some responsibility on our vendors and have benefited from participating in trade shows and implementing more formalized training programs.

We also reach emerging talent by partnering with technical colleges within the United States and neighboring countries. Our college outreach has been incredibly successful, with us hiring a dozen employees from one international school within a two-year period. Bringing in that external talent enables us to invest in our local community with those employees moving to the area and buying houses nearby.

Can you describe some of the specific challenges you encountered during that 25-tool package project, and how your team overcame them to meet the deadline?

Heusser, Jr.: We had years of experience working with this customer on various tooling projects, which familiarized us with their system. We had always managed five or fewer tool projects simultaneously, so effective project management was critical. Fortunately, the system that we have in place enables us to deliver tools and sample parts on time, whether it’s one tool or 25.

Daily morning meetings keep the team on track, ensuring each job progresses as planned and remains on schedule.

Recovering from the pandemic presented some challenges for the project, but we always managed to find a solution. Whenever we anticipated a delay, we communicated promptly. Similarly, if we believed we would finish ahead of schedule, we communicated that as well. The project went so well that the customer added another mold onto the package, bringing the total delivered tools to 26 within their window.

Projects like this have positioned us well to collaborate on reshoring, nearshoring and new program builds. This particular project sparked interesting conversations with individuals both within and beyond our usual customer base.

The words of Robert Heusser Sr. still resonate within the halls of Rutledge: “Know your customers, know what they want and how we can help them.” This philosophy will guide the Heusser family and the Heico Companies as they lead Versatile Mold and Design into the future.

Related Content

Next-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Read MoreHigh-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MoreOpenness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreRead Next

Innovation, Diversification and Integration Guide Mold Builder Growth

Quality Tool and Die team discusses the journey from a small automotive tool shop to a diversified full-service moldmaking and plastic production facility.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreR&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read More