Analysis

Standardizing Inspection

Standardizing inspection on a single software has allowed this automotive toolmaker to lower training expenses, offer greater staff flexibility and improve CAD compatibility.

Read MoreMake a Local Connection, See Innovations and Test Your Leadership

Looking for a way to treat your mold manufacturing team to an evening of fun, all the while having the chance to view new products and services, network with colleagues and help a great industry cause?

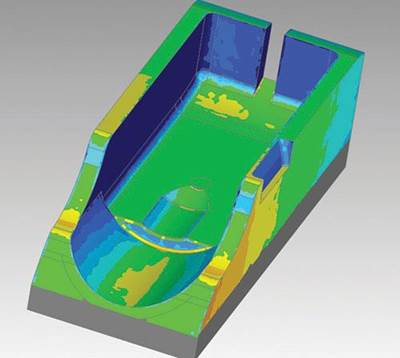

Read MoreToolpath Verification Optimizes CNC Machining Productivity

One shop estimates that the addition of Vericut software has helped it increase throughput as much as 20-30 percent.

Read MoreMeasuring Odd-Shaped Parts with a DCC CMM

This video outlines a cloud of points measurement feature of a portable DCC CMM using built in control software.

WatchMeasurement Right on the Shop Floor

Portable, direct computer controlled coordinate measurement can streamline processes and reduce inspection backlog for a better bottom line.

WatchTaking Control of Measurement Tool Inventory

An automated asset management system that tracks usage and calibration schedules for measurement tools helps cut costs and improve customer service.

Read More3D Scanning Offers Wide-Ranging Benefits

One mold manufacturer reports not just faster mold inspections, but also the capability to error-proof electrodes and accelerate product development.

Read MoreStreamlining Cooling Water Tests

This shop takes advantage of combination chiller/temperature units that pack all needed functionality into a single, independently controlled, machine-side system.

Read MoreFrom Bottleneck to Project Accelerator

Laser scanning provides new inspection options and a faster alternative to CMM for this engineering and mold manufacturing company.

Read MoreIncorporating 3D Printing

Technologies that give moldmakers the ability to test out a couple different designs before investing in the final tool.

Read More