Aluminum

Dispelling Aluminum Tooling Myths

Myths have always been around: the world is flat and the sun revolves around the earth— to name a few.

Read MoreFive Reasons to Consider Aluminum Tooling

Today many original equipment manufacturers are under tight restraints, such as cost, new product development and time-to-market, giving mold builders an enormous opportunity to develop the necessary technology to support today’s plastics industry.

Read MoreFour Facts about High-Performance Copper Alloys

Improve your global competitiveness by using high-performance copper in your molds.

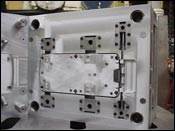

Read MoreThe Realities of Aluminum Tooling

Using aluminum tooling instead of traditional tools steels reduces cycle time and costs, but requires up-front, open communications between moldmaker, molder, material supplier and hot runner manifold supplier.

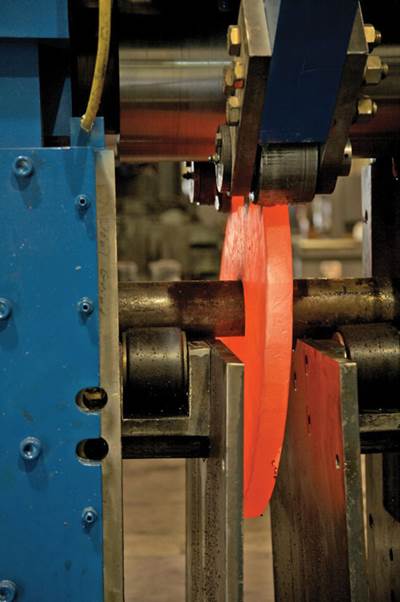

Read MoreTwenty Years of Copper Alloys in Moldmaking

A look at where we are today with the integration of copper alloys in mold building.

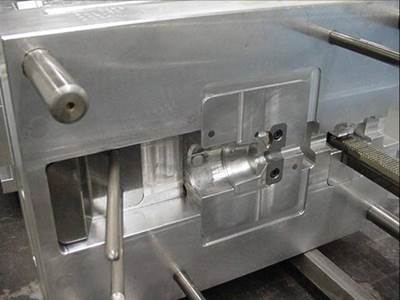

Read MoreNew Design Strategy for Generating Hybrid Aluminum Tooling

Design, machining and analysis software aids in aluminum mold manufacture.

Read MoreDispelling Myths of Rapid Tooling

Six myths of rapid tooling will be dispelled by examining the truth. This will enable the moldmaking and injection molding industries to better accept and sell the growing trend of aluminum tooling.

Read MoreSelecting a Carbide End Mill for Aluminum Applications

Specific geometries and characteristics of a carbide end mill are required for efficient machining of aluminum.

Read MoreBreaking Down the Cost of High Conductivity Copper Alloys in Moldmaking

Improving productivity with high conductivity copper alloys.

Read MoreMaking the Most of High-Performance Mold Materials

Understanding high conductivity alloys and optimizing their use can help you build better molds.

Read More