Aluminum

Reaching the Next Level of Efficient Machining

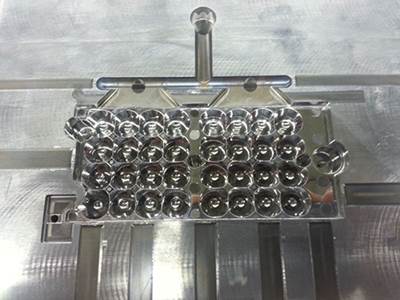

Clamping devices can help to achieve fast and efficient mold plate and cavity/core insert changes during machining.

Read MoreMoldMaking Technology's March Digital Ed Is Now Available!

MoldMaking Technology's March issue features technical articles on texture repair, aluminum tooling, building a mold in fewer setups, how not to troubleshoot in mold maintenance, moldmaking opportunities in NAFTA markets, and much more.

Read MoreIs Your Concept of Production Costing You Money?

Common misconceptions about aluminum tooling may affect your next mold material selection.

Read MoreLet’s Be Clear About Aluminum

Within the injection molding industry, a negative perception of aluminum for anything but prototype plastic parts persists, despite aluminum tooling being able to produce and run almost any resin that steel can, as well as produce millions of shots with unfilled resin with uniform results.

Read MoreMaximize Results with Copper Alloy Molds

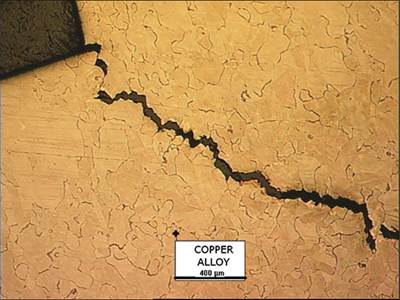

These most common mistakes can lead to failure in the application of copper alloys in mold tooling.

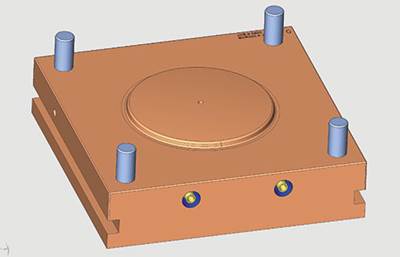

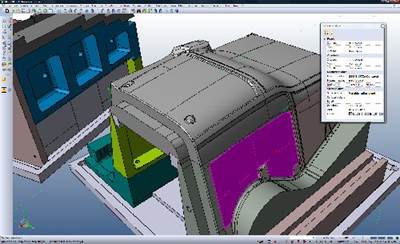

Read MoreDesign Collaboration Produces Tooling Right First Time

DeltaCAD Ltd collaborates with sub contract tooling manufacturer Casting Support Systems on a project to provide a leading aerospace company with aluminum tooling for a carbon composite seat shell for a major civil airline company.

Read MoreTake a Second Look at Production Aluminum Tooling

One moldmaker has put aluminum tooling to the test and advises a second look for your high-volume automotive applications because it can address your quality, cycle time and cost challenges.

Read MoreTaking Streamlining to the Next Level

Based in Rochester, NY, Aluminum Injection Mold Company (AIM; Rochester, NY) is an industry pioneer in providing creative production aluminum tooling solutions to a wide range of markets including automotive, medical, computer / business machines, telecommunications and consumer products since 1985.

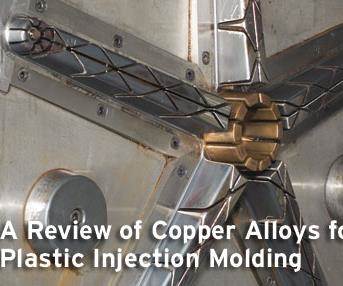

Read MoreA Review of Copper Alloys for Plastic Injection Molding

Copper alloys are attractive to the mold industry because of their high thermal conductivity, ease of machining by a variety of processes, and corrosion resistance to water, cooling fluids and the plastics being injected.

Read More