Multi-Laser Powder Bed Fusion 3D Printer Supports Complex Mold Building

Using its FormUp 350 system, AddUp, in collaboration with Siebenwurst Group, improved the conformal cooling channels for a mold slide.

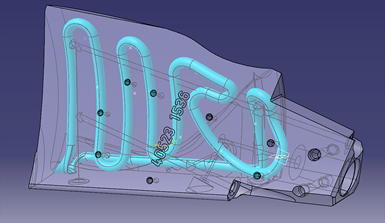

A collaboration between the Siebenwurst Group, a global toolmaker, and AddUp Inc. to improve a mold slide for plastic injection molding, demonstrates the benefits of AddUp’s FormUp 350 powder bed fusion (PBF) machine.

The FormUp 350 is a multi-laser metal AM system, with a 350 × 350 mm build surface, ideal for tooling applications. AddUp’s proprietary roller technology delivers reduced supports and optimal surface finish, providing solutions to manufacturers looking to maximize quality, productivity and ROI. According to the company, it is also capable of meeting mechanical and geometric properties (up to 0.1 mm dimensional accuracy) and material density, and can be used for all types of metal powders, even reactive ones. A laser accuracy of 35µm is achieved.

Because the FormUp 350 is a four-laser system with full field scanning and a robust stitching capability, it is well-suited for parts on the larger end of the PBF spectrum. The platform also offers several features to boost safety and productivity. For example, the Autonomous Powder Module reduces powder exposure to the machine operators. It also allows for faster turnover between builds, ensuring the capacity to print more parts with less time spent on powder handling and setup times.

An example application performed successfully on the FormUp 350 is a mold slide created for the Siebenwurst Group. Using its PBF printer and expertise in additive manufacturing (AM), AddUp assisted with the design, simulation and print of the mold slide — using AISI 420 steel — with improved cooling channels. The ability to use channels that conform to the contours of the mold enabled the plastic to cool and reach ejection temperature more quickly. The operating temperature of the steel dropped by about 60°F as well.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.