Uddeholm USA

2505 Millennium Dr.

Elgin, IL 60124 US

800-638-2520 | 630-883-3100

sales.usa@uddeholm.com

uddeholm.com/us/en-us

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

Uddeholm USA Supplies the Following Products

- Beryllium Copper

- Beryllium Copper Substitute Alloys

- Coatings, Plating Services

- Copper Alloys

- Material for Additive Manufacturing—metal

- Stainless Steel

- Tool Steel/Mold Steel

Trade Names Offered by Uddeholm USA

Editorial, News, and Products

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

-

Tried-and-True Plus New Technology to Level Up Your Mold Shop

In this most recent roundup, MMT continues to present a variety of innovative and proven technologies, mold materials and services to target the ever-evolving moldmaking industry.

-

VIDEO: Innovative Materials Boost Mold Efficiency

Advancements in metal 3D printing and stainless steel optimize mold building for diverse, high-demand industries.

-

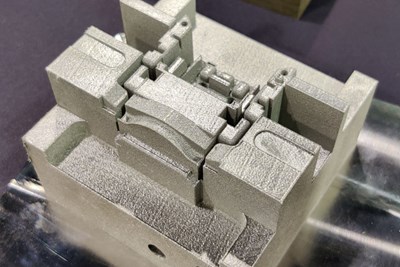

Mold Material Enables Additive Manufacturing Capabilities for Tooling

Uddeholm USA features its mold material Corrax as the first additive manufacturing (AM) powder made for tooling. Corrax is a stainless steel made for AM with corrosion resistance and polishability.

-

Overcoming Barriers to Automation Integration in Precision Moldmaking

It’s easy to imagine the advantages automation offers the moldmaking process, but it's challenging to change one’s mindset, develop a plan and invest.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Xact Metal, Uddeholm Partner to Offer Corrax Tool Steel Powder

Moldmakers and molders will have access to a mold steel capable of an A1 surface finish post-polishing, supporting the industry’s expansion into metal 3D printing.

-

Corrosion-Resistant Mold Steel Designed For Polishability

NPE2024: Uddeholm showcases its Tyrax ESR mold steel that combines toughness, corrosion and wear resistance.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

Most-Viewed Content of 2022

The most popular MoldMaking Technology content according to analytics reports over the past 12 months.

-

The MoldMaking Conference: All About Next-Level Mold Maintenance

Here we spotlight the Maintenance block of sessions of the MoldMaking Conference – for the next-level mold manufacturer – November 8 & 9 in Charlotte, North Carolina.

-

Corrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s premium Tyrax ESR can reduce polishing time by 40-50% and is suitable for long run production molds and high-performance plastics.

-

WEBINAR: Tool Steel Demands and Enhancements

Pressurized electro-slag refining and powder metal production techniques remove impurities when producing highly alloyed stainless steel grades specifically for moldmaking. Listen to this free webinar to learn about current trends in the plastics industry, next-generation stainless tool steels, production techniques and additively manufactured parts and components.

-

Stainless Mold Steel Exceeds Toughness, Corrosion and Wear Resistance

Uddeholm offers its latest mold steel Tyrax ESR for longer tool life, and faster polishing for reliable production of high-performance plastic parts.

-

Building Confidence in AM for Tooling

New potential for tooling applications is reached with custom-designed materials for additive manufacturing.

-

Can You Recommend Any Books on Mold Design and Manufacturing?

Mold industry pros rally to offer a list of resources in response to a fellow SPE member’s call for assistance.

-

2019 Technology Review: Mold Materials

MoldMaking Technology’s 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including mold materials.

-

Considerations for AM Powder for Tooling

The start of any good product is the raw material, and that includes additive manufacturing powder for tooling.

-

The Most Viewed Products of 2018

MoldMaking Technology wraps up the year by showcasing the most-viewed products of 2018.

-

AM Powder Designed to Create Conformal Cooling Channels

With so much happening in a busy show year between NPE2018, Amerimold 2018 and IMTS 2018, MoldMaking Technology is revisiting some of the technology that was on display. In case you missed it: Uddeholm says that using Corrax additive manufacturing powder enables the creation of conformal cooling channels to reduce cycle times. The company had the powder on display at NPE2018.

-

Voestalpine Additive Manufacturing Seminar

Not a day goes by when we do not hear or read about the transformational opportunities offered to manufacturers by additive manufacturing.

-

2018 Technology Review and Sourcing Guide: Mold Materials

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold materials.

-

Steel Offers High-Corrosion Resistance for Longer Service Life

With so much happening in a busy show year between NPE2018 and Amerimold 2018, MoldMaking Technology is revisiting some of the technology that was on display. In case you missed it: Uddeholm says that Mirrax ESR possesses a unique combination of qualities across large cross sections to meet the increasing demands of plastic mold tools.

-

Strategic Shifts Enable Transition to Full Plastic Molding

Edro has become the exclusive distributor of Bohler tool steels and a distributor for all MoldMAX Alloys for plastic applications in Europe and North America. It has also added a warehouse in Schaumburg, Illinois.

-

Uddeholm Celebrates 350 Years of Tool Steel Manufacturing

Uddeholm announces its 350th anniversary as a manufacturer of industrial tool steels in 2018.

-

Tradeshow Tuesday: Coming Up at NPE2018

Cruise through this week’s slideshow to see more of what’s coming up at NPE2018.

-

Mexico: Manufacturing Mecca to the South

A mold-building perspective on Mexico’s manufacturing opportunities, trends and challenges.

-

Cutting Tool Trends and Observations

At Ingersoll Cutting Tool’s annual Die and Mold Seminar, there were many new and different products to learn about, but as important was hearing the trends in cutting technology.

-

Defining Mold Steel Toughness

Consider grades that have undergone the electroslag remelting process.

-

SLIDESHOW: Technology Showcase – Mold Materials

Tool steel, aluminum, copper and alloys are some of the materials used to manufacturing molds, and the choice of materials to use is critical to the overall performance of the mold.

-

PVD Coatings and Tool Steel Selection

Mold users are driving an increased use of physical vapor deposition (PVD) coatings, and this has generated questions and concerns from mold builders as they select materials from which to manufacture their molds. PVD coatings are a family of very thin (approximately 2 to 5 microns) metal layers applied in a vacuum chamber using a plasma process.

-

The Economics of Metric

Why pay extra for inches when world economics is moving the U.S. into the metric age. Will this motivate the U.S. to convert in the next two years?

-

Specialized Apprenticeship Training

We hear plenty about the lack of skilled workers within our mold building facilities, but we can't ignore the fact that that same problem plagues our technology suppliers. Here is one steel producer's take on this challenge.

-

From the Field: The Right CAD/CAM Makes New Mold Manufacture Easier and the Entire Process More Efficient

Fine, tiny detailing demanded by model railway enthusiasts requires moldmaking tolerances in manufacturing scale models that are often tighter than those in the automotive industry. With the right CAD/CAM system creating the mold around the designed product takes approximately 30% less time than it did with the CAD/CAM system PECO used before switching to VISI.

-

Tool Steel and Aluminum Staying Strong

A roundtable of mold material suppliers discuss how new offerings result in easier machinability, better weldabilty, increased strength and improved surface hardness.

-

New Developments in P/M Steels for Moldmaking

Highly alloyed steels are difficult to manufacture using conventional steel melting methods.

-

Development of a New Mold Base Stainless Steel

Due to the intensive machining practices that must be performed on mold bases, if machining time and costs can be reduced, significant savings can be realized. A premuim free machining stainless holder steel has been developed that has optimized chemistry and processing, which lead to greatly improved machinability as well as other important properties.

-

Selective Materials Strategy Is A Potent Tool for Moldmakers

Reducing mold build costs with different steels and coatings may give North American shops more business from electronics OEMs.

-

Spray Form Technology Fills the Gap in Plastic Mold Tooling

New method for producing steel yields significantly better overall tooling economy.

-

Packaging Molds Go High-Tech to Improve Productivity and Economy

The ability to design and build innovative molds for advanced processing needs is key to being competitive and profitable in a low-margin market.

-

Cost Savings for Mold Materials: Consider the Details

Ways to reduce costs that are not related to the price per pound of the mold material.

-

Breaking the H-13 Stereotype For the Common Mold

A look at the new grades and steel making practices that are available to address the day-to-day issues that occur in the operation of a mold.

-

It's a Material World

Strength, hardness and machinability are the common buzzwords that come into play when examining the new materials on the market.

-

Ensuring Mold Steel Polishability

When working on a project that requires high-quality texturing or surface finish, using an electro-slag quality material may be the best option for mold steel.

-

Choosing Thermally Conductive Tooling Materials

By using alternative materials such as aluminum or copper-based alloys, moldmakers can help molders reduce or eliminate some molding problems down the road.

-

Hanging Tough

Fallout from the recent imposition of tariffs on steel imports may raise domestic steel prices and further drive business out of the country.