LSR Platform Meets Critical Medical Molding Needs

NPE2024: Recent updates to Mastip’s Aquilo platform highlight how its design — from consistent thermal profile to uniform cooling — has made it successful for medical industry projects.

Mastip Inc. is introducing the latest updates to its Aquilo liquid silicone rubber (LSR) systems and looks forward to sharing its experiences with recently completed projects for the medical industry.

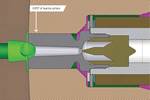

Mastip’s LSR solution features a “cold deck” design that includes cooling channels in the mold plates, manifolds and nozzles. This design ensures the mixed material remains in its uncured condition before entering the heated cavity plates.

Additionally, the use of valve gating technology improves balance between cavities and from shot to shot, eliminating material curing in the gate between cycles. Sequential timing of the valve gates is the key component that ensures cavities are kept balanced.

Mastip’s dedicated CR04 and CR06 LSR nozzles are designed with cooling channels extending toward the valve gate nut, ensuring a consistent thermal profile along the nozzle. This design enables optimal control of the valve gate nut temperature which Mastip says is critical in consistently producing high-quality LSR parts.

The consistent thermal profile along the nozzle also ensures that LSR flows smoothly and uniformly into the part, resulting in a high-quality gate and improved part quality overall. This is especially important in industries where precision and quality are critical, such as medical device manufacturing.

Related Content

-

Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

-

Moldmaker Highlights Domestic Mold Expertise for Plastics Industry

MSI Mold Builders has the ability to develop a full range of injection molds and structural foam molds domestically, meeting the needs of U.S.-based molders.

-

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

.jpg;maxWidth=300;quality=90)