MMT Blog

November Technology Roundup: Mold Materials & Miscellaneous

November’s Technology Showcase includes Hasco, Marposs Corp., Slide Products, Steel 21, Walter USA, Siemens, DP Technology, United Grinding, Uddeholm USA and more.

Read MoreStreamlining Your Search for Solutions

You’ve had some time to experience MoldMaking Technology’s reorganized and redesigned website, so now it’s your turn to share what you like best.

Read MoreTraining and Education Is Major Focus with the Tooling Divisions of The Plastek Group

This manufacturer of plastics packaging also manufactures injection and injection blow molds across three facilities employing more than 125 well-trained toolmakers, engineers and project managers.

Read MoreHow to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

Read MoreSwitching from Solid Carbide to Indexable Tooling Permits Lights Out Mold Base Manufacturing

The unique design of small-diameter, indexable high-feed milling cutters eliminates cutter breakage, improves productivity, and allows lights out mold base manufacturing.

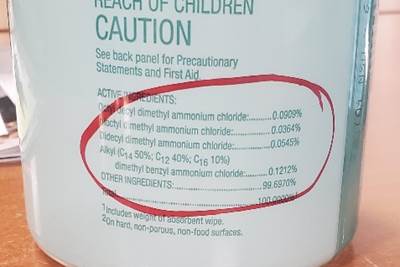

Read MoreALERT: An Unintended COVID Consequence

Are you experiencing unexpected oxidation and severe pitting on your molds and mold components? Well, it could be due to the additional cleaning the coronavirus has forced upon shops this year.

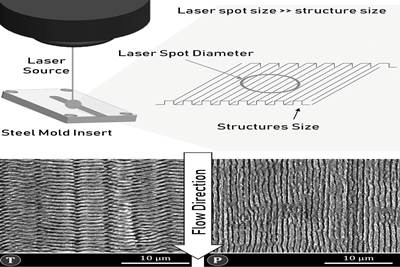

Read MoreA Look at Three Mold Surface Effects

Identifying and testing innovative injection mold surface properties became an unexpected theme of recent virtual content—ultrafast laser texturing, coatings and plasma.

Read MoreMMT Chats: Surge in New Orders Drives Moldmaking Index Expansion

Gardner Intelligence Chief Economist Michael Guckes shares insight on the recent strong move of the Moldmaking Index due to higher readings across all business activity components of the Index, highlighting the surge in new orders.

WatchHigh-Performance Alloy Increases Performance Capability of Aluminum Molds

DRS Industrial’s use of high-performance aluminum alloys helps it build better molds faster and at a lower cost, improving molder productivity.

Read MoreAchieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.

Read MoreFive Ways to Tackle Tough Mold Design Tasks with Digitalization

Transform static 3D designs into animated 4D designs that simulate motion and interaction of complete mold systems to improve design workflow.

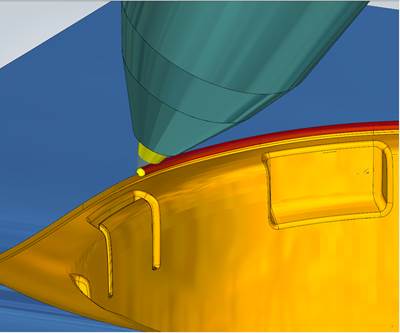

Read MoreHow to Select the Right Programming CAM Software for Directed Energy Deposition in Mold Repair and Modification

Selecting the right programming CAM software improves the use of directed energy deposition to repair and modify tooling.

Read More