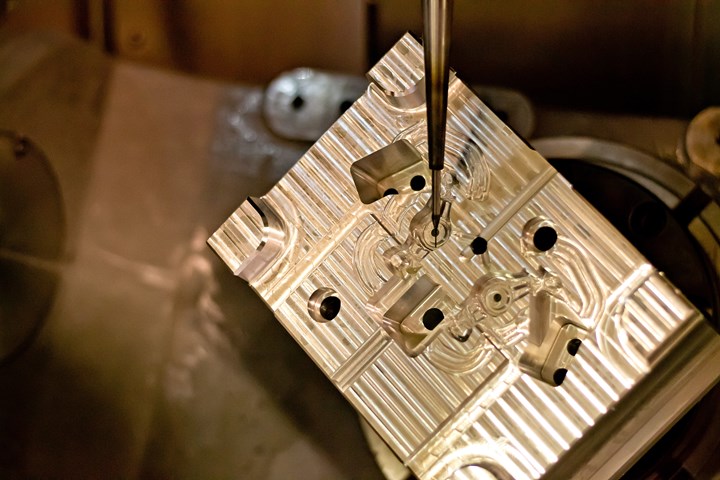

Based on 7000 series alloys, new aluminum grades specifically designed for moldmakers and commercial injection molds were introduced about a decade ago. Although harder than typical aluminum alloys, these specialty grades machine faster and easier, and their heat treatment provides more even stress distribution, decreasing warpage. The premium materials offer outstanding through-thickness strength, stability and durability, plus high thermal conductivity, improved corrosion resistance and tight grain structure, allowing them to be rough-milled 8-10 times faster than steel. Far more than just a bridge between 7000 series aluminum and tool steels, these premium aluminum grades have actually replaced P20 in production molds and increased tool durability to half-a-million shots or more assuming proper maintenance is followed. Image courtesy of Constellium.

DRS Industrial LLC (DBA DRS Industries) is a Holland, Ohio-based moldmaker specializing in prototype and production aluminum tooling for injection molding. The ISO 9001:2015-certified company builds three to four new aluminum molds perweek sized for platens up to 36 by 60 inches/91 by 152 centimeters and presses up to 730 tons/tonnes. DRS serves a diverse base of customers in the aerospace, consumer, automotive/ground transportation, telecommunications, appliance and medical-device markets. Not only does it design and build injection molds and offers mold tryout services, but DRS operates a custom-molding business with value-added secondary finishing and assembly. In-house presses range from 95 to 730 tons/tonnes; for larger parts, partners offer presses to 3,500 tons/tonnes. Moldmaking and molding operations are housed under a single 40,000-square-foot/3,716-square-meter building, and DRS owns a second, 10,000-square-foot/929-square meter off-site warehouse where it stores production molds for customers.

Over the past few years, between trade wars and tariffs, DRS occasionally ran into sourcing issues with the premium aluminum alloy—which the moldmaker uses for roughly one out of every four molds it builds. Given the tight turnaround DRS quotes on its tools, having to wait several days for material put the company at risk of missing deadlines and disappointing customers. A chance visit from a salesman from aluminum supplier Constellium led to DRS trying Alumold 500, which behaved just like the premium alloy they’d been using. Image courtesy of DRS Industrial LLC.

“We really work with a broad range of customers,” chuckles Craig Simon, DRS president. “Not only do we service large, multinational OEMs but we also support Shark Tank-type inventors who create their own products that we produce for them. It keeps things interesting.”

All in for Aluminum

When DRS was founded in 1982, the company produced injection molds and mold patterns for castings in both steel and aluminum. “Around 1985, we saw the writing on the wall and moved in the correct direction to build a better tool,” recalls Dan Jahns, DRS sales manager, who notes that the company’s focus shifted at that point to aluminum injection molds. Although they still produce an occasional steel tool to meet specific customer needs—usually an aerospace mold requiring an A1 finish—the company has long championed the numerous benefits that aluminum brings to most injection molding applications.

“Since aluminum’s less costly to start with and you can machine it 8-10 times faster than steel, it allows you to produce a mold with the shortest possible lead time at the smallest customer expenditure,” explains Simon. “You can get a multi-cavity aluminum mold at lower cost than a single-cavity steel mold—and you can get it quicker, helping you get to market faster.”

“The benefits don’t stop there,” adds Jahns. “Because of aluminum’s high thermal conductivity and diffusivity—it heats and cools five to eight times faster than steel—molders can reduce cycle times 20-50% in the same part thickness, or mold thicker parts in the same cycle time, or mold thin-wall parts much faster with less risk of warpage. That means higher productivity and profitability from the same presses. It also simplifies a tool’s cooling system. Since you get better temperature distribution with fewer hot spots, cooling lines are straighter and you don’t need all the crooked trees with baffles and bubblers like you do in steel. And that’s another benefit aluminum brings: it adapts faster and more readily to engineering changes. Since cooling doesn’t have to be so precise, if a change is needed, it probably won’t affect cooling-line placement as it would in steel. Aluminum is very forgiving that way.”

“Aluminum is truly a bridgeable material enabling you to move from prototype right into production tooling,” continues Simon. “It’s used for series production in high-volume industries like automotive, appliance, consumer electronics and sporting goods. Although we’ve seen aluminum tools support production requirements as high as one-million parts, today’s model changes are being made more frequently, so piece counts aren’t as high as even a decade ago. Also, because aluminum tools are lighter than steel ones, you’ve got less mass hanging off your press, so there’s less wear on everything from bushings to bearings to platens. That means you can mold at lower clamp tonnage using less energy. Even in our own shop, we’ve literally seen platens last two to three times longer when the press only ran aluminum tools rather than steel.”

“Unfortunately, with wide use comes wild use,” muses Jahns. “Most certainly, not every grade of aluminum can be used for series production. Too many people choose the cheapest alloy and act surprised when the tool fails. The problem isn’t the failure; the problem is jumping to the conclusion that aluminum isn’t suitable for series production when the wrong alloy is used.”

“When a shop knows how to build an aluminum tool and a molder knows how to run that tool, it’s hard to beat the economics.”

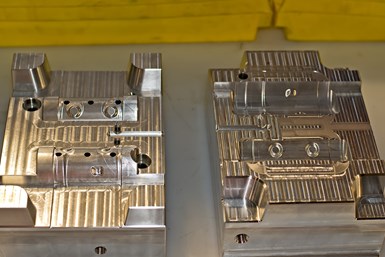

DRS Industries of Holland, Ohio is a moldmaker specializing in prototype and production aluminum tools for injection molding. The ISO 9001:2015-certified company builds three to four new aluminum molds perweek and also operates a custom-molding business with value-added secondary finishing and assembly. Image courtesy of DRS Industrial LLC.

Premium Alloys Gain Popularity

DRS uses 5000 series alloys for prototype and low-volume molds as long as they aren’t running high-temperature polymers. Most of its tools are constructed from 7000 series alloys, which offer some of the highest strength aluminum grades on the market. That makes them good choices for high-temperature and abrasive plastics and for bridge tooling options into lower-volume production runs over many years.

A decade ago, aluminum molds got a performance boost when Alcoa Corp. (Pittsburgh) introduced QC-10, a specialty grade within the 7000 series that was one of the first aluminum alloys specifically designed for moldmakers and production injection molds. The material offered outstanding through-thickness strength, stability and durability with a quench-insensitive microstructure providing consistent machining through the entire thickness of the plate. With high thermal conductivity, improved corrosion resistance and tight grain structure, the material could be rough-milled 8-10 times faster than steel, EDM’d, polished to a very-fine finish (SPI A2) and textured. It provided excellent machinability with small chips, few burrs and fast CNC feeds and speeds. The alloy was supplied in thicknesses of 1.0-24 inches/2.5-61 centimeters fully wrought, tempered and stress relieved.

This new type of alloy proved a boon for moldmakers and molders. Its performance was so much higher that it opened up new opportunities for aluminum in higher stress molds. Although harder than typical aluminum alloys, it machined faster and easier, and its heat treatment provided more even stress distribution, decreasing warpage. Far more than just a bridge between 7000 series aluminum and tool steels, it actually replaced P20 in many production molds and increased tool durability to half-a-million shots or more, assuming proper maintenance was followed. Other aluminum suppliers commercialized similar products and, before long, moldmakers like DRS found themselves using a lot of premium aluminum alloys.

The new grades had their challenges. “Early on, owing to the precipitation heat-treatment process suppliers used, the alloy wasn’t available in thicknesses greater than 10 inches (25 centimeters), so we had to learn to make our molds with lots of plates and avoid deep pockets,” recalls Simon. “That meant we could have split lines in cosmetic areas of the part.” It took a few years, but that problem was solved and premium alloys are now available in thicknesses up to 32 inches/81 centimeters.

When DRS was founded in 1982, the company produced injection molds and mold patterns for castings in both steel and aluminum. By the mid-1980s, the focus shifted mainly to aluminum injection molds. Although they still produce an occasional steel tool to meet specific customer needs, DRS has long championed the many benefits of aluminum tooling, including lower cost, faster machining, faster mold heating and cooling with fewer hot spots, simplified mold cooling systems, less wear on press components and higher productivity and profitability from the same presses. Image courtesy of DRS Industrial LLC.

“During the last few years, between trade wars and tariffs, we couldn’t always get material when we needed it,” continues Jahns. “We quote really tight turnarounds on our tools. If we have to wait two to three days for material, we’re going to miss a deadline and disappoint a customer. We needed another source of premium alloys.”

At a point when DRS faced sourcing issues and was calling distributors trying to find quick access to high-performance aluminum alloy, a cold call by a sales rep from the Ravenswood, West Virginia offices of aluminum supplier Constellium (Paris) led to a new source of specialty alloy. “At the time, we hadn’t been buying Constellium alloys, but this salesman asked us to give their premium material—Alumold 500—a try and he showed up next day with exactly the stock we needed and hadn’t been able to get,” recalls Jahns. “We made a tool with Alumold 500 and it behaved just like the alloy we’d been using—both in terms of machining and molding customer parts. Given that 25% of the molds we produced last year required premium aluminum alloy, we were thrilled to know that our supply challenges were behind us.”

Specifically Designed for Molds

“When our industry first started looking at aluminum alloys for toolmaking, it began with alloys developed for aerospace,” explains Sergio Buttignoni, Constellium segment leader-molds. “However, those materials offered different properties than moldmakers needed. One critical and non-negotiable requirement we quickly learned is that moldmakers need through-thickness consistency of mechanical properties—and in a much broader range of thicknesses than the aircraft industry uses. We also knew that to ensure a uniform surface finish—whether polished or textured, and achieved via chemical etching or laser engraving—the substrate needed a fine and uniform microstructure, plus we had to develop a way to restore that surface if it got damaged. Add to that the importance of high hardness and corrosion resistance, fast and efficient machinability and greater durability and you can see what was involved in developing premium alloys like Alumold 500 for injection molds. Thanks to the high hardness and strength of this material, molds in Alumold 500 perform better and last longer than those made with general 7000 series alloys. It has to because it’s competing against a much-stronger material—namely steel. This helps ensure moldmakers and molders remain competitive without having to take extra risks they don’t like.”

Although available for a decade, Constellium reports that interest in Alumold 500 as a mold material is growing. The specialty alloy can be used for molds operating at temperatures up to 120°C/250°F; for higher-temperature resins—up to 200°C/392°F—Constellium has developed a high-temperature alloy called Alumold 350 that’s a true alternative to steel and is ideal for blow molds for hot-fill application as well as thermoplastic elastomers and composites. Image courtesy of DRS Industrial LLC.

Alumold 500 can be used for molds operating at temperatures up to 120°C/250°F. “Fortunately, that range includes all commodity resins and 70% of the plastics market,” adds Buttignoni. “For higher-temperature resins—up to 200°C/392°F—we’ve developed a high-temperature alloy called Alumold 350 that’s a true alternative to steel and is ideal for blow molds for hot-fill applications. It’s also excellent for molding thermoplastic elastomers and composites.”

While Alumold 500 has been commercially available for over a decade, Buttignoni reports interest in the material and sales are still increasing. “These alloys are now recognized as high performance and available—not an insignificant factor,” he adds.

“When a shop knows how to build an aluminum tool and a molder knows how to run that tool, it’s hard to beat the economics,” concludes Simon.

About the Author

Peggy Malnati is a Detroit-based contributing writer for MoldMaking Technology focused on case study/application stories and shop profiles. She has also been a contributing writer for CompositesWorld since 2006, for which she primarily covers automotive and ground transportation.

A long-time member of SAE and SPE, she has organized and managed large technical sessions and conferences for both organizations as well as for the former Structural Plastics division of SPI. For 15 years, she was a board member and the communications chair for the SPE Automotive Division. She also was editor of the 1994 McGraw-Hill book Structural Analysis of Thermoplastic Components. She has provided writing and communications services for the global plastics and composites industries since 1984.

Related Content

Aluminum Machining Efficiency Improved With Milling Inserts

The TungAluMill line has been enhanced with 10 new XVCT-AM inserts, featuring an interface design that augments machining at high speed rates.

Read MoreCast Plate Aluminum Alloy is Suitable for Production Mold and Dies

Alimex Precision in Aluminum introduces its 7000 series ACP7 mold material, featuring high mechanical properties, material stability and good machinability.

Read MoreFive Benefits of Aluminum Tooling

Aluminum molds are worth a second look as a viable means to swiftly and cost-effectively get products to market.

Read MoreTechnology Review and Sourcing Guide 2024: Mold Materials

Building a high-quality mold requires the proper selection of appropriate mold materials. Tool steel, aluminum, copper and alloys are a just a few examples you can fin in this exclusive, online-only content that includes a supplier list for mold materials.

Read MoreRead Next

Addressing Aluminum Tooling Objections

Mold builder shares the technical and financial advantages it experiences using aluminum tooling.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;width=70;height=70;mode=crop)