MMT Blog

U.S.-Built Mazak Machines Making EMO Debut

Mazak Corporation (Florence, KY) is displaying Kentucky-developed and built machine models at EMO 2011, taking place this week in Hannover, Germany.

Read MoreGraphite-Mold Casting Process Yields Cost Savings for Lens-Cutting Machine Maker

A leading manufacturer of lens processing equipment is saving time and money, thanks to an economical casting process. A part that was, until recently, made up of four individually machined pieces is now being produced as a single, economical casting that is more rigid and more stable than the old four-part assembly.

Read MoreMold Business Index: Overall Business Levels Uneasily Steady

Total Mold Business Index for July 2011: 50.0

Read MoreThe Mold Shop Puzzle: Competition Applied

Creating Constructive Change: Competition Applied

Read MorePowdered Metal Technology Creates Opportunities

PMT is an injection molding process that can produce precision mold cavities at high volumes with high repeatability.

Read MoreSocial Networking, Industry Participation Keys to Moldmaker’s Success

Industrial Mold & Machine (IMM; Twinsburg, OH) considers itself fairly diverse. A majority of the company’s work is smaller molds (under 400 tons) in industries like appliance, computer/business equipment, electronics, lawn and garden, marine, medical/optical/dental, telecommunications and toys.

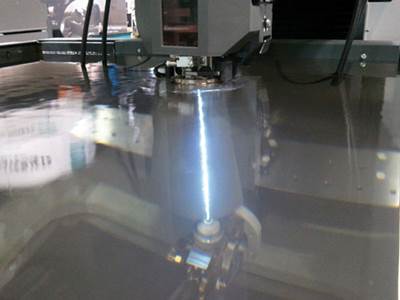

Read MoreReducing Energy Usage with Wire EDM

Technology advances have helped make today’s EDMs environmentally friendly.

Read MoreMacro Considerations for Cutting Tool Selection

Selecting the best cutting tool is a critical activity to your business success. It’s a re-occurring job that directly impacts cycle time and your shop’s competitiveness.

Read MoreStrategic Partnerships Solidify Automotive Niche

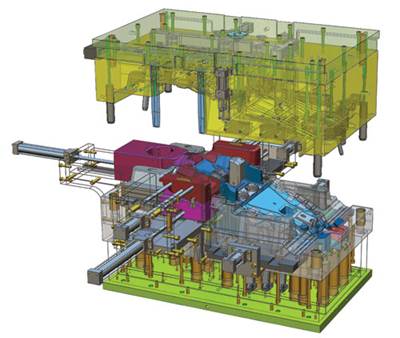

To further strengthen its reputation as a leading innovator in the marketplace, Proper has recently formed strategic alliances with German company KrausMaffei and Woburn, MA-based Trexel Inc.—two vastly different organizations with their own specialties.

Read MoreAchieving Real Cost Savings with Paperless Moldmaking

True cost savings from a paperless approach comes from a streamlined process with fewer steps and faster time-to market.

Read MoreHow to Better Utilize Your Existing Equipment

It is time to begin to rebuild capacities and get the highest utilization out of your current shop equipment.

Read MoreHow to Get the Most Out of Carbide Recycling

By choosing the right recycling program, mold manufacturers can help sustain both the environment and their industry.

Read More