MMT Blog

Color Matching for Mold Weld Repair

Experience and careful attention to detail are the key requirements to a predictable and consistent color match.

Read MoreApply Your Moldmaking Know-How to Aerospace Work

If you are looking to diversify the jobs you machine and venture into the aerospace market many of the toolpaths and cutting techniques can be used with some modifications.

Read MoreFive Ways to Bridge the Skills Gap

As the U.S. moldmaking industry continues toward economic recovery, finding the right worker for the job is a huge concern. In the past, entry-level machinists could be hired with little experience; yet today’s computerized machines and higher levels of automation demand a deeper skill set, even for beginners.

Read MoreFive Important Tax Changes Beneficial to Your Shop

On December 17, 2010 President Obama signed The Tax Relief, Unemployment Insurance Reauthorization, and Job Creation Act of 2010 (2010 Tax Relief Act) that includes important depreciation and IRC Sec. 179 deduction changes, which were retroactive to September 9, 2010 and will benefit both large and small manufacturers.

Read MoreDiverse Mold Offerings Sustain Moldmaker, Secures Future Business

Pelco Tool & Mold, Inc. (Glendale Heights, IL)—a producer of close-tolerance, high-quality tools for the closure, food and beverage, personal care, and medical industries—designs and builds a plethora of molds, including, single face and stack, rotating ratchet ring (RRR), conventional unscrewing, strip, side-action, collapsible core, compression, front-loaded core, insert and prototype.

Read MoreGet Out and Stay Out

Here’s a classic water-cooler joke for you: BOSS: Get any orders on your customer visit today? SALES REP: Sure, I got two orders! “Get out” and “stay out.”

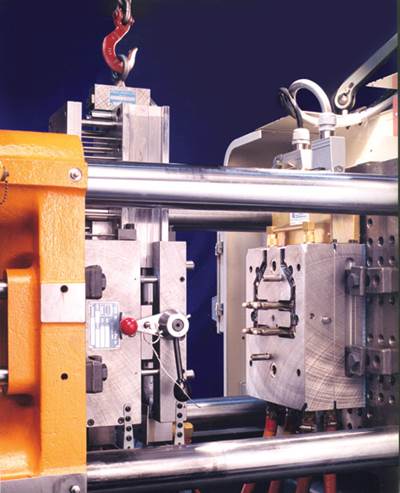

Read MoreHow Moldmakers Can Reduce Production Costs and Maintain Precision

Using a mold base quick-change/hot runner combination in your mold designs can result in flexible, interchangeable precision.

Read MoreUnderstanding Customer Expectations

An informal survey reveals what OEMS are looking for in their tooling vendors.

Read MoreSimple Strategies for Providing Value-Add to Your Customers

Five technology solutions to consider that have advantages for both the mold manufacturer and its customers.

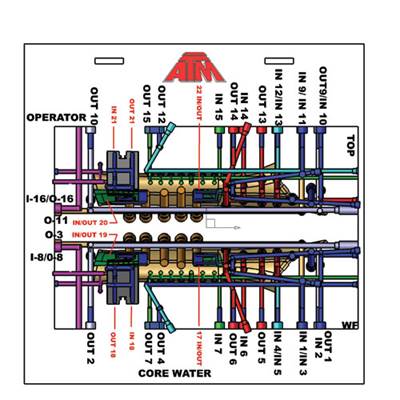

Read MoreStäubli Quick Mold Changing Systems: Innovations in Plastics Processing

Based on its extensive knowledge in changing and connecting molds, Stäubli has developed a complete line of products designed to improve changeover times in plastics processing.

Read MorePowerful Slide NEXGEN Metal and Mold Cleaner Contains No Trichloroethylene and No Methylene Chloride

NEXGEN metal and mold cleaner is a direct alternative to Trichloroethylene and Methylene Chloride, and is one of the most powerful, most effective natural cleaning solvents you can use on molds and metals, as well as a variety of other challenging cleaning applications.

Read More