Achieving Real Cost Savings with Paperless Moldmaking

True cost savings from a paperless approach comes from a streamlined process with fewer steps and faster time-to market.

The tooling industry has seen many new technologies, methodologies and initiatives. The initiatives range from going green, do more with less and—most prevalent in the drive to paperless manufacturing—knowledge capture and reuse. And while the paperless manufacturing environment can clearly reduce costs through the elimination of printed drawings and machine instructions, the real cost savings from a paperless approach comes from a streamlined process with fewer steps and faster time to market.

Technology has taken us from drawing boards and paper prints to computer workstations utilizing first 2-D, then 3-D wireframe, and now full solid modeling to define tool designs and manufacturing processes. Today we even have smart, portable devices that can literally bring the virtual engineering world to our finger tips. Most of the data that used to be recorded by hand on forms or worksheets can now be entered into and managed in any one of a number of computerized systems in both engineering and on the shop floor.

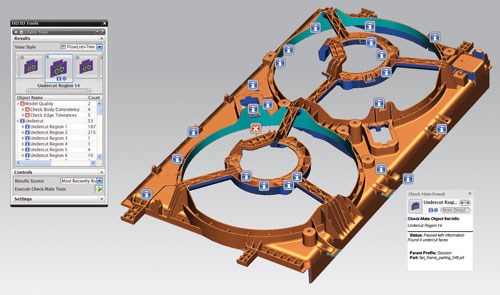

Paperless manufacturing could be viewed as a methodology of interweaving some of these new technologies to meet your automation initiatives. For example tool design software doesn’t just replace the manual methods of design on paper; it provides all sorts of automation to make the designing task faster, easier and more repeatable.

While the use of almost any computerized system—from CAD/CAM to ERP—will reduce the need for paper-based methods there are some less obvious ways in which the use of a paperless approach can offer real business value. In this review we will take a look at a number of examples.

Early Customer Collaboration

Today many toolmakers will find themselves working with large companies that use a product data management (PDM) system to manage the flow of data internally and externally for both current and new product projects. They may have a mechanism in place to allow suppliers to log-in to a specially controlled area of the system.

By aligning or forming a partnership with these customers and being granted this type of entry into their systems, a toolmaker may be in an excellent position to do more than just download job requirements as electronic data files rather than receive traditional drawings or hard copy specifications. By collaborating electronically and early in the overall project the toolmaker may be able to help influence the design of their customer’s product especially in the field of manufacturability. This can save time and money when it comes to the tool design and manufacturing process. And, by becoming a preferred supplier to a customer you may find you have a head start over your competitor for business.

Unified Engineering and Manufacturing Platform

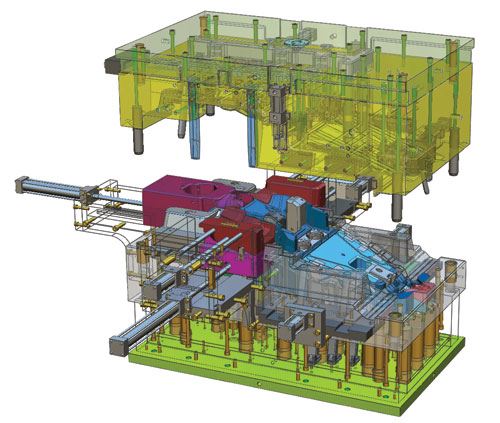

Once the tooling business is won and customer data is obtained (hopefully by electronic methods) we can look at another opportunity to derive additional value from the full use of a paperless system. Most toolmakers will have software applications for CAD, CAM and maybe for CAE (analysis and simulation), but all too often these are standalone products that are deployed separately in design engineering and manufacturing. The big problem with most combinations of these solutions, even though it could be considered paperless, is that the resulting overall design to manufacturing workflow is typically non associative.

As an example of a non associative workflow, a company could have one generic CAD tool that is used to import customers’ data and prepare it for mold design (edit draft conditions, material wall section, blends, etc), then a second CAD system to design the mold and yet a third (CAM) system to generate NC programs to drive machine tools.

If a generic data format, such as IGES or STEP, is used to translate data between each of these systems the time taken to do this is not only dead time (i.e. has no added value to the production process), the cost of that time can add up—fast, without engineering or manufacturing taking place. Inject an engineering change from the customer into this process and the costs continue to mount.

By investing more up front in a fully integrated CAD/CAM solution that can perform all the design and manufacturing tasks without the need for data translation, tooling companies can reduce costs but have the extra time to take on significantly more jobs to boost their revenue and reputation (see Sidebar).

Automating the Process

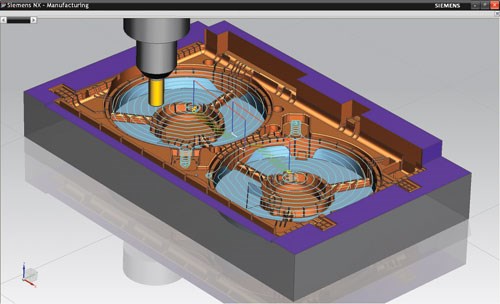

Another advantage of using closely connected, paperless systems is that today’s technology can allow more than just the geometry to be passed from stage to stage. In the past, much of the detailed specification data such as tolerances, surface finish requirements and so on were still detailed on a drawing as a part of the design process. To refer to these requirements downstream users, such as NC programmers or quality inspection programmers, would typically use a drawing print as a reference.

Today we can add most of this data to the 3-D model definition as PMI (product manufacturing information). This can be defined according to national standards for formatting associated with dimensions, tolerances or surface finish. Alternately, a more informal, company-specific method could be employed, such as the use of surface colors added to the model where design and manufacturing have agreed that certain face colors represent the need for different levels of surface finish or tolerance.

In either case the latest CAM and CMM (coordinate measuring machine) programming software can be set up to read this non geometric data and use it to drive NC programming or the creation of quality inspection programs automatically. In the CAM area this is often coupled with the use of feature based machining (FBM) technology. The result is not just the further reduction of the use of paper as the need to read this data from prints is diminished, but also the CAM or CMM programming productivity is dramatically increased. Another important benefit of this kind of paperless automation is a reduction in errors. Automated programming driven by PMI type data is not only amazingly fast compared to normal interactive programming methods, it’s also virtually error free once the system is configured.

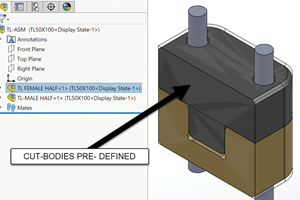

Shop Floor Delivery

Making the 2-D and 3-D mold design information available through computers on the shop floor can virtually remove the need for paper prints in the stage of the process where they are still most commonly seen. The mold designer will continue to create assembly and component drawings electronically, but not printing the drawings for the shop can reduce the cost of paper, ink and copying supplies. But once again the real value comes from other aspects of this.

First, the data access and view on a display screen can be controlled based on the user’s role or log in. Depending on the system controlling the data, shop floor users can be given access only to the latest working data, reducing the risk of working from the wrong revision or an old print. Just one mistake in the used the wrong drawing category can cost the profit on a tool.

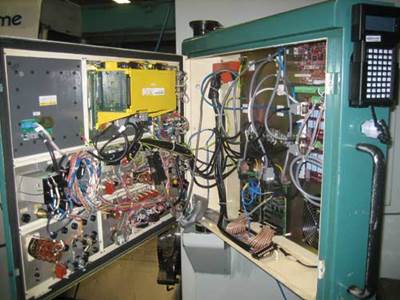

The same applies to the delivery of CNC files to a machine tool. Although paper tapes for transporting NC programs went out years ago, replaced with electronic data files today, there are still tool lists and set up sheets and drawings to be delivered as a part of the work package. While the use of electronic systems for DNC (Direct Numerical Control) to connect to machine tools is a standard capability, it’s less common to make the rest of the work package available in electronic formats right at the point of use, such as in the work cell, at the tool presetter and so on. The availability of low cost, large, flat display screens as big as 24 inches or even more, makes the viewing of complex data and drawings much more viable than it used to be on older equipment.

All of this can be considered a part of the paperless environment and the viewing technology is relatively simple. The critical step that can add significant value is managing the source of the data that’s being accessed in this paperless world.

Data and Process Management

A paperless environment implies the widespread, perhaps complete, switch to electronic data. This brings with it the opportunity to be just OK or to be world-class. OK could mean just using basic PC-based file managers, explorers, folders and home-designed file management. The alternative uses the latest in engineering data management to manage all of the information created or needed at each stage of the process.

These systems are designed to manage all types of engineering information, to understand what each data file represents, manage its revision and release status as well as control who can see and who can edit every item. For example, when the “save” button is selected in the CAM software the full set of data that is being worked on, including NC output files, setup sheets, tool lists and more, can be stored automatically under the correct program and job reference. The data set is attached to a manufacturing process reference under full revision control. All this means that anyone can go back and find that exact set of data for that job, for that revision and so on. This greatly reduces the risk of data errors, reduces the time spent looking for the right data, and makes it easier to go back and pick up the good examples as a start for the next similar job.

The Final Pay Off

This approach of managing data really starts to pay off when we use it as the basis for providing a work package for access on the shop floor. We can set the approved data set for Job X into a shop floor accessible section of the system, with full release status on it. Using web style browsing technology we can provide access for shop floor users to any part of that released work package, even allowing them to connect directly to a machine tool. We can do this without sending the data over to a separate, standalone shop floor PC where it can become less controlled or duplicated. This can be really useful for shops where being able to demonstrate data control and security is a key requirement imposed by customers.

All of the above are elements of the paperless environment story. The true value of being paperless is in the productivity and efficiency derived from the way in which you chose to handle the resulting electronic data, and in the type of systems that you use to create, to move and to manage that data. Remember, data becomes valuable information when it’s managed and used in the correct context.

Related Content

VIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreHow to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreRead Next

Measuring the Effectiveness Of Your Mold Machining Ops

A review of the shortcomings and solutions to OEE challenges.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More