Powdered Metal Technology Creates Opportunities

PMT is an injection molding process that can produce precision mold cavities at high volumes with high repeatability.

Powdered metal technology (PMT) combines the technology of plastic injection molding and powder metallurgy to create a new process. The powdered metal technology process involves metal powders being mixed with a binder that is granulated to feed into an injection molding machine. A mold is designed and manufactured to create the cavity part for the injection mold. Green parts are molded and after a multistep process to separate the binder from the metal, cavities are ready for any post molding work.

These parts, which are typically made from H-13 tool steel, can then be heat treated. After heat treating, PMT cavities can be machined like any other cavity from hardened tool steel. Machining processes such as EDM, grinding, etc., are no issue and this ability allows for engineering changes at a later date, if necessary. Since PMT cavities are produced from a mold, any engineering changes can be made to the mold that produces the PMT cavities and new PMT cavities can be molded and machined for new part revisions.

This technology can enhance the capabilities of any moldmaker and help reduce the cost and increase the delivery for high cavitation injection molds. Since this process allows for PMT cavity duplication from a master mold, the greatest advantage of using this technology is that it guarantees that all cavities are precisely the same, regardless of volume or date of manufacture. Extremely precise PMT cavity reproduction is possible. Other key features of PMT include:

- Cavities are H-13 tool steel, with other steels available depending upon the application

- Can be heat treated to standard Rockwell hardnesses

- Can achieve surface finishes of up to Rmax 2

- Cavities can be coated for corrosion resistance (TiN, nickel plate)

- Short pull ahead times for duplicate cavities, including spares

From a moldmaker and end user standpoint, PMT allows them to produce higher cavitation molds that may have been too difficult or too costly with making cavities conventionally. PMT offers an excellent economy of scale, suitable for high cavitation molds—typically 16 cavities and higher. Since a master mold must be designed and manufactured to create the PMT insert, the cost of this mold must be taken into account when producing cavities. The cost of the mold can be amortized into the piece price of the individual PMT cavities or the mold can be paid for separately, lowering the individual PMT cavity piece price. A moldmaker has to consider the cost and benefit for the PMT technology based on cavitation. This is best for higher cavitation molds since the higher the number of cavities, the lower the cost to produce each cavity.

Depending upon the size and configuration of the cavity detail to be produced, feature tolerances of up to 15 microns are achievable. In addition to repeatability of the cavities, high cavity definition can be achieved with PMT—fine details and sharp corners are easily produced. This is possible because the impression of the master mold for the PMT cavity takes the green part shrinkage into account. The part features in the master mold will be larger than those in the finished part, making them easier to machine. Also, the mold impression will be opposite of the finished parts. A recess in the final cavity is produced by a standing feature in the mold. This external, standing feature can be machined with sharp corners. This will translate into a sharp corner feature in the finished cavity, unlike conventional machining on a cavity, which can be limited based on machine cutter radius or EDM overburn.

Figure 1 shows a magnified view of cavity detail in a PMT cavity insert. Also using PMT, if a special design for the cavity is needed for the mold design, these cavities can be produced with unique shapes that would be difficult or impossible to produce with other metalworking processes.

However, not all cavities can be made using PMT. There are limitations as with other technologies. Because of the process used to make PMT cavities, cooling in the injection mold of the finished cavities must be accomplished externally. Waterlines cannot be designed into these cavities. Typically, PMT cavities are inserted in plates, and then these plates are cooled from the mold base that contain water lines. Even with this limitation, this process has allowed molding cycle times on PMT cavities as short as 3.2 seconds on small plastic parts.

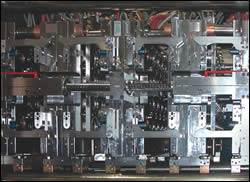

Another limitation is the maximum size of the cavity. The maximum PMT cavity size is 25mm x 30mm x 70mm, but can change based on the complexity of the cavity to be made. Figure 2 shows a range of different shapes and sizes of finished PMT cavities.

For moldmakers who are thinking about designing and making high cavitation molds, PMT mold cavities takes some of the issues, cost and leadtime to make cavities out of the equation. For moldmakers that are already manufacturing high cavitation systems, this would also be an excellent option to employ when making these molds to help cut costs and leadtime. This technology can help lower individual cavity cost and can also reduce labor and machine time and cost. The additional labor and machine time that is not used machining cavities can be used toward other parts of the project to reduce overall leadtime. With the high level of repeatability and precision, and a lower cost per unit that PMT offers, this is a great technology to use for this type of work.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

High Cavitation Molds Promote Economies of Scale

Toolmakers are developing increasingly complex molds for high production of thinwall parts.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More