MMT Blog

Book Your Reservations for NPE 2012

Book your reservations now through EXPOVISION the official NPE2012 housing office in order to secure your hotel.

Read MoreInternational Plastics Design Competition Gets Underway as Entry Submission Opens at www.Plasticsdesign.org

Organized by SPI, the 2nd IPDC Will Culminate at NPE2012 with a Prominent Display of Submitted Parts or Products and a Gala Awards Presentation.

Read MoreNew NPE Magazine

A 24-page special publication covering every aspect of the upcoming NPE2012 event.

Read MoreEnd Market Reports

Market Outlook: Motor Vehicles; Market Outlook: Aerospace Products and Parts

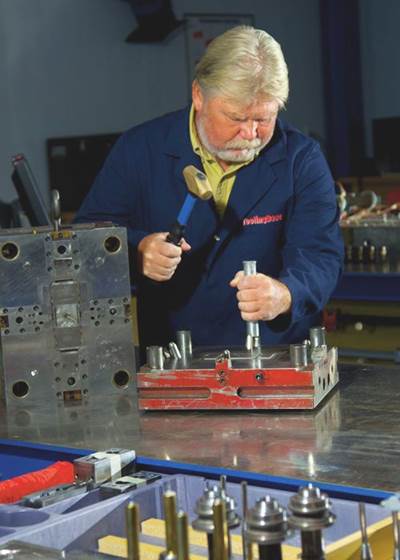

Read MoreCorrosion Control: A Guide to Proper Mold Care

If you have not set up a proactive mold maintenance program, your facility runs efficiently only until the next major problem or repair.

Read More