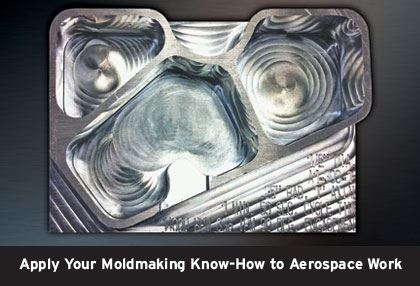

Apply Your Moldmaking Know-How to Aerospace Work

If you are looking to diversify the jobs you machine and venture into the aerospace market many of the toolpaths and cutting techniques can be used with some modifications.

Newer toolpaths for hardened material are being used in aerospace machining. For example, trochoidal toolpaths are now utilized for aluminum, titanium and nickel alloys. Cutting tool geometries now take full advantage of these new toolpaths.

One way to capitalize on the new toolpaths and reduced cycle times is to eliminate the vibration (chatter) that commonly occurs in aluminum parts. Mirror edge geometry on an end mill makes the vibration of the part match the vibration of the tool; therefore, eliminating chatter and vibration (see Figure 1).

Typically you can machine aluminum parts with mirror edge geometry at a depth two times the tool diameter in one pass. For example, you can machine 1” deep per pass with a ½” tool without any vibration or chatter. Common radial step-overs are about 50 percent of the tool diameter per pass. The example part 6”x 4” and 1” deep was machined in just 1minute 50 seconds using geometry that took advantage of newer tool paths (see Figure 2).

Another common application in the aerospace market is thin wall machining. Mirror edge geometry is even more critical in thin wall parts due to the tendency of thin parts vibrating. Thin wall parts require the use of tools with short cutting lengths and reduced diameter necks to reach the depth needed (see Figure 3). Toolpaths for thin wall parts are similar to that of die/mold components except you rough and finish the entire part at every Z-level.

For example, if the part has two pockets, rough pocket 1 and finish pocket 1, then rough and finish pocket 2 until the whole part is finished at each Z-depth. Also leave about .100” of material on the walls for your finish pass (see Figure 4). By utilizing this technique, the thin walls will not push out of the way in front of the cutter and it is possible to machine very thin parts (see Figure 5).

These are just a couple of the applications in aerospace that demonstrate the common ground between the moldmaking and aerospace industries.

Related Content

-

Tolerancing in Mold Design, Overcoming Cutting Tool Vibration, SPE MTD Updates & More Most-Viewed May Content

Every month, MMT draws inspiration from its diverse readership's wide-ranging interests, from mold design tolerancing to cutting tools and beyond. Here are May’s top 10 most-viewed articles, based on Google Analytics.

-

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

-

How to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

.png;maxWidth=300;quality=90)