Power to Change

Paragon D&E's ‘Power to Change’ motto entails its team working together to create methods for doing things more efficiently and trusting their decisions. A key component to that philosophy is its powerful CAD/CAM software.

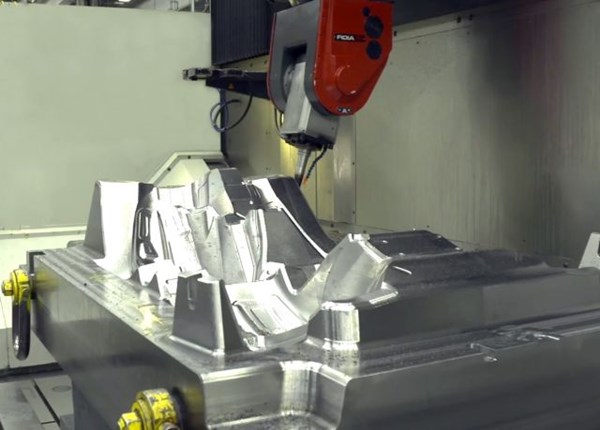

Paragon D&E's ‘Power to Change’ motto entails its team working together to create methods for doing things more efficiently and trusting those decisions. Standardizing all of its machining on Delcam’s PowerMILL CAM software has helped live up to this philosophy.

"Delcam isn’t just another software provider,” says Andrew Samrick, Vice President of Manufacturing. “We’ve been given regular training onsite. We’ve got some great ‘mad scientists’ who can think up these incredible things. PowerMILL has helped us to take their focus off the day-to-day issues and to begin to look forward.”

Another driver for this technology shift was the lack of skilled labor. This prompted Paragon to find technology that takes the labor that they have and apply it across more machining time, according to President David Muir.

They also started a training programm within the company in 2013 called Paragon Technical University that allows the company to put apprentices on the right path for the right career choice. They have 26 currently working.

“Now that we are using the same software throughout the plant, an apprentice that is learning PowerMILL in the small machine department can go over to another department more quickly as he already has Delcam knowledge," says . Dean of PTU, Larry Oppenhuizen.

Click here for the full interview.